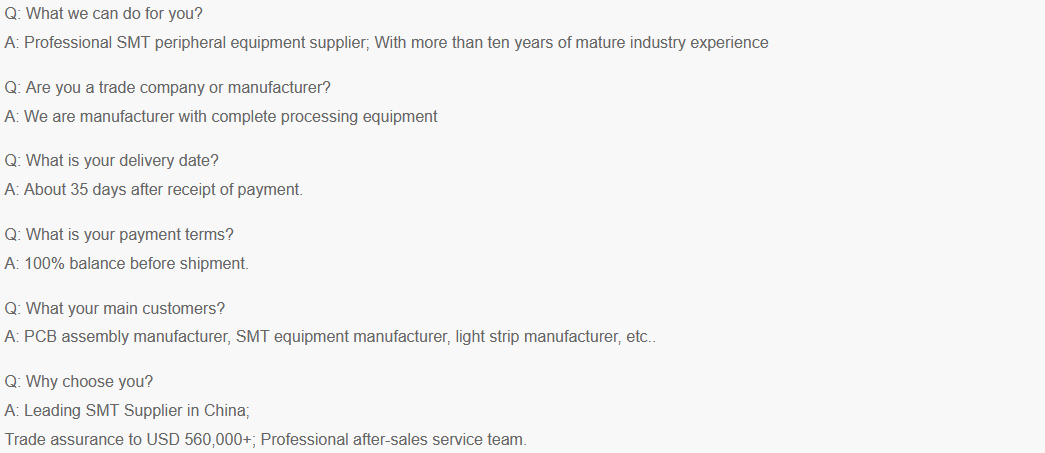

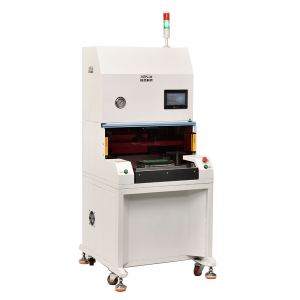

Servo Hydraulic Punching Machine

✧ Features

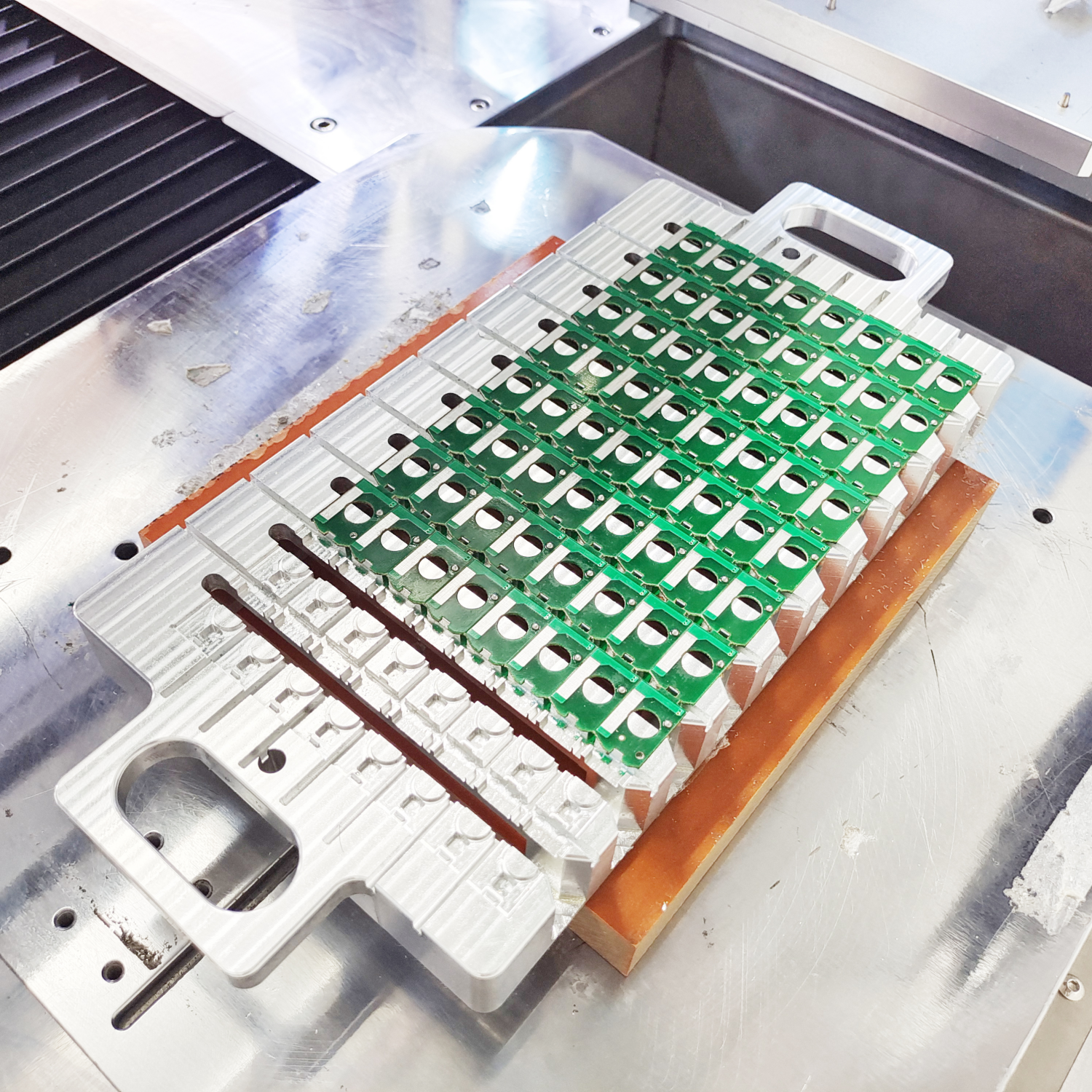

1. Using servo hydraulic punching, the speed is fast, and the cutting speed is 8 seconds per whole piece:

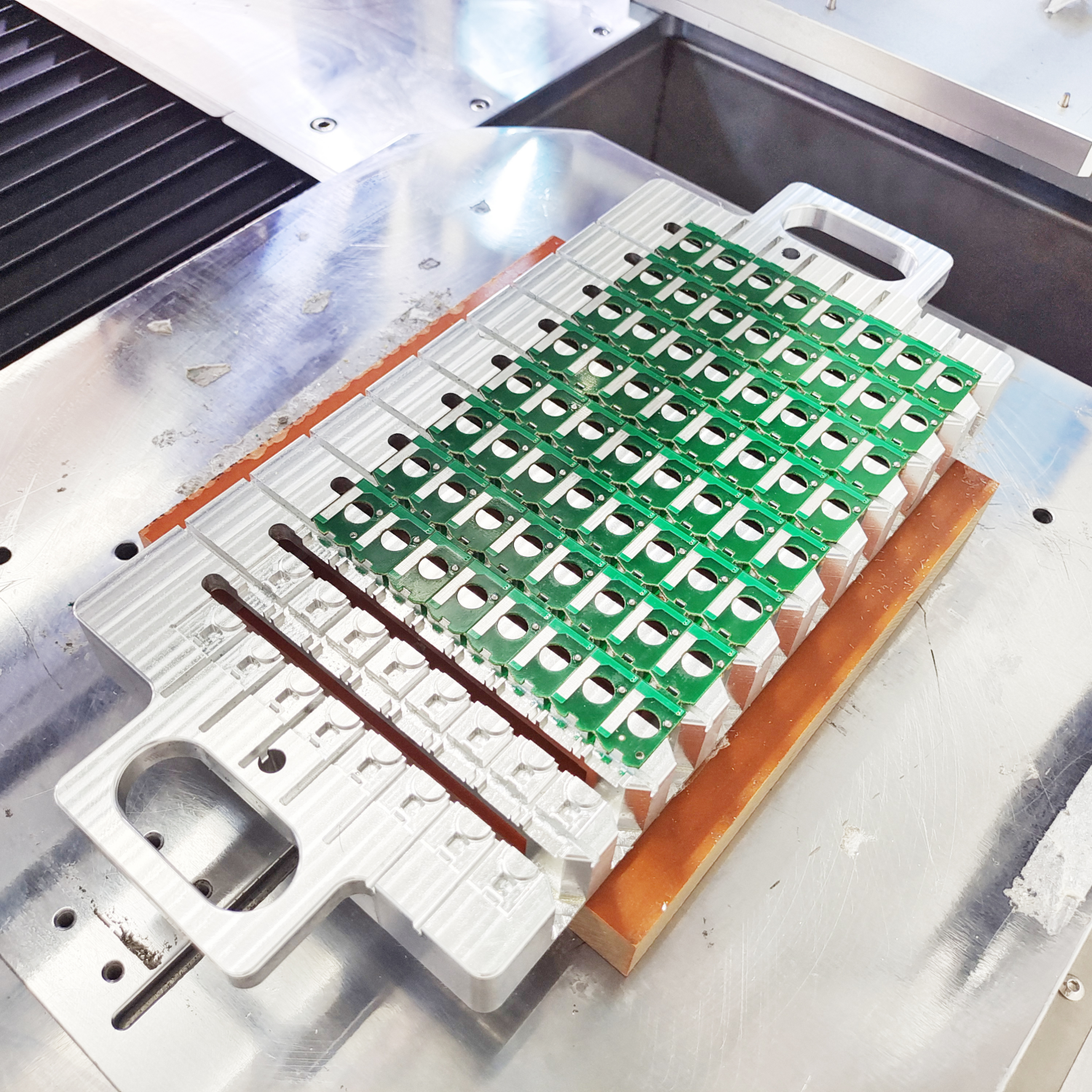

2. It is suitable for cutting all kinds of FPC splicing board connected on the whole surface, with a cutting accuracy of ±0.03mm, the pressing stroke can be set arbitrarily, and it has the function of half-breaking the whole board;

3. Punching pressure is 30 tons, with oil pressure and temperature measurement alarm function;

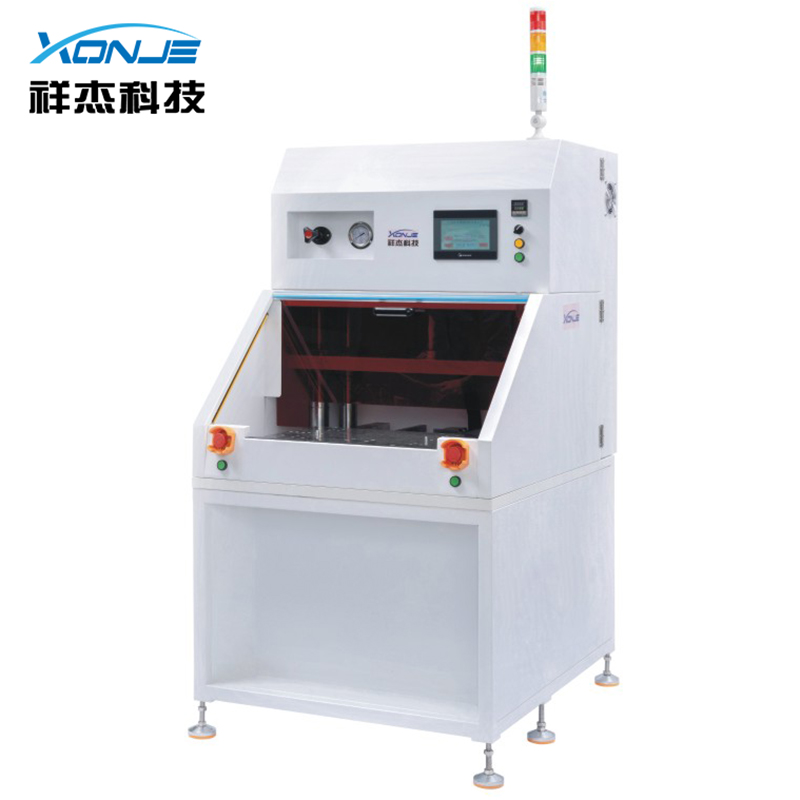

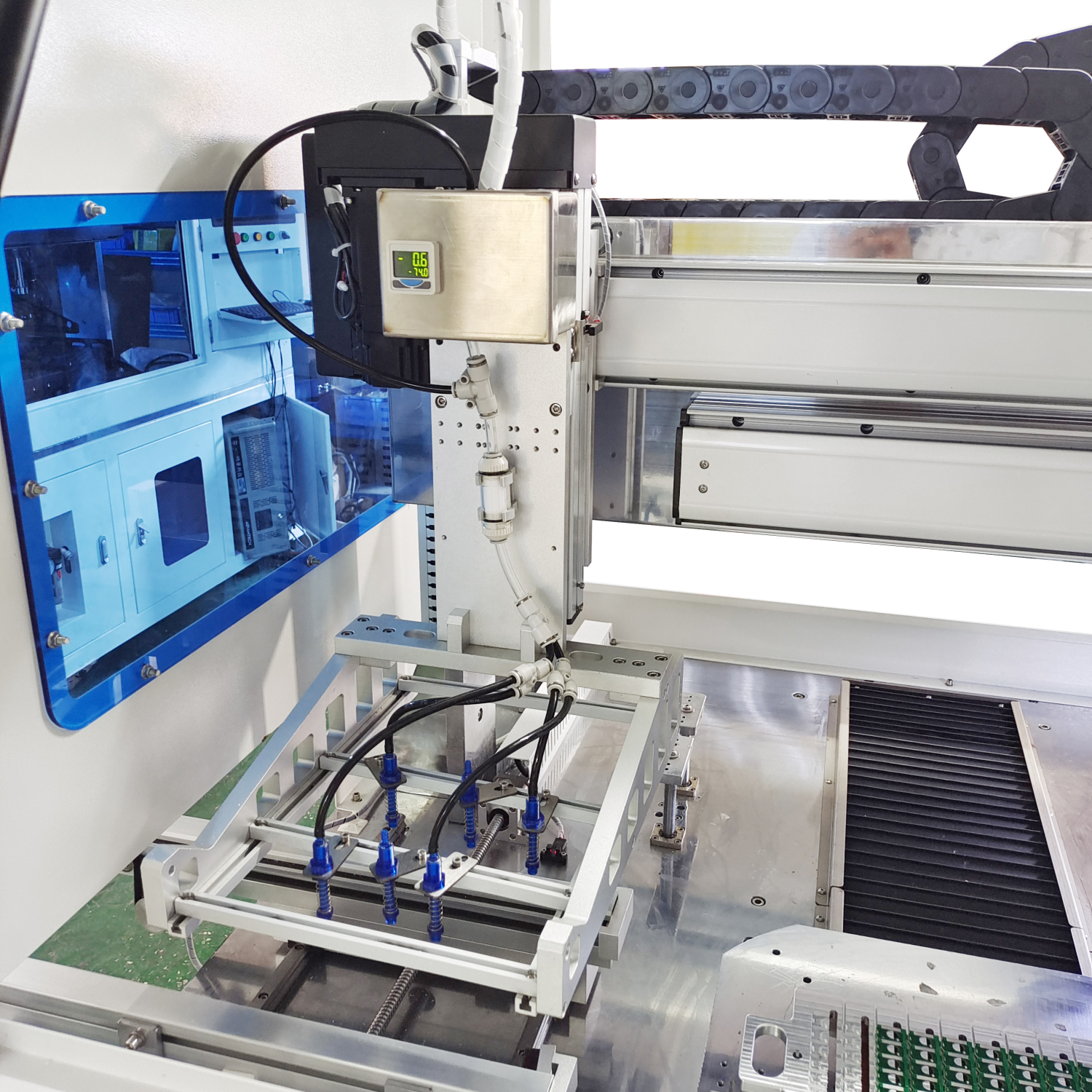

4. Cutting table size(L*W)460mm*400mm;

5. The sliding accuracy of the platform, the horizontal accuracy of the platform and the mold table is ±0.02mm, composed of servo motors, servo drives, sensors, etc., through the control system to complete the front and rear sliding of the platform, so as to realize the FPC handling function;

6. The maximum die thickness of the die size:T=100mm, which can be cut normally;

7. High-precision guide rods, high-quality oil cylinders, oil pumps, Panasonic motors, multi-oil pipelines, proportional valves, solenoid valves, etc. complete the punching function, Through the control system, the pressure can be fine-tuned, and the downward pressure and cutting can be stable;

8. Drawer type of cutting worktable(cutting table top automatically returns to the operating position after cutting), using servo motor to drive fast and high precision;

9. The production quantity of the touch screen display equipment can be set arbitrarily: the number of pieces produced by the equipment can be manually set by the user;

(1) The device pressure will display the measured value.

(2) The equipment pressure can be set in the touch screen. When entering the pressure adjustment interface, a non-operator password is required to unlock the parameters to adjust the parameters. The operating area has a safety protection device.

10. Control system

(1) Realize emergency stop under abnormal conditions, and set sound and light alarm

(2) Abnormal situation realizes emergency stop, and set sound and light alarm

(3) Emergency stop buttons and alarm devices are installed at both ends of the equipment

(4) The control panel is locked to prevent unauthorized personnel from modifying and setting parameters

(5) Equipped with an independent power distribution cabinet, the circuit is divided into functional blocks, strong current and weak current blocks , easy to maintain

(6) The system sets up an overload protection system

11. Touch screen

(1) Operation authority can be set, control methods: point touch, manual, semiautomatic, output storage, statistics and error information storage

(2) In the parameter setting(engineer level: setting authority is required),the program(each station)can be selected and set, real-time monitoring, parameter setting and so on.

✧ Technical Parameter

| Operation mode | Servo oil hydraulic system |

| Force output | 25T/30T/50T/80T |

| Place the board area | 350*500MM |

| Use voltage | 380VAC |

| Working pressure | 0.5-0.7MPA |

| Machine weight | 750KG |

| L*W*H | 1160*910*1800MM |

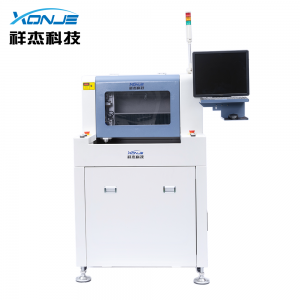

✧ Equipment Introduction

--Optional operating system, dual development of windows and Linux operating systems, approved by Huawei. Safer and more open

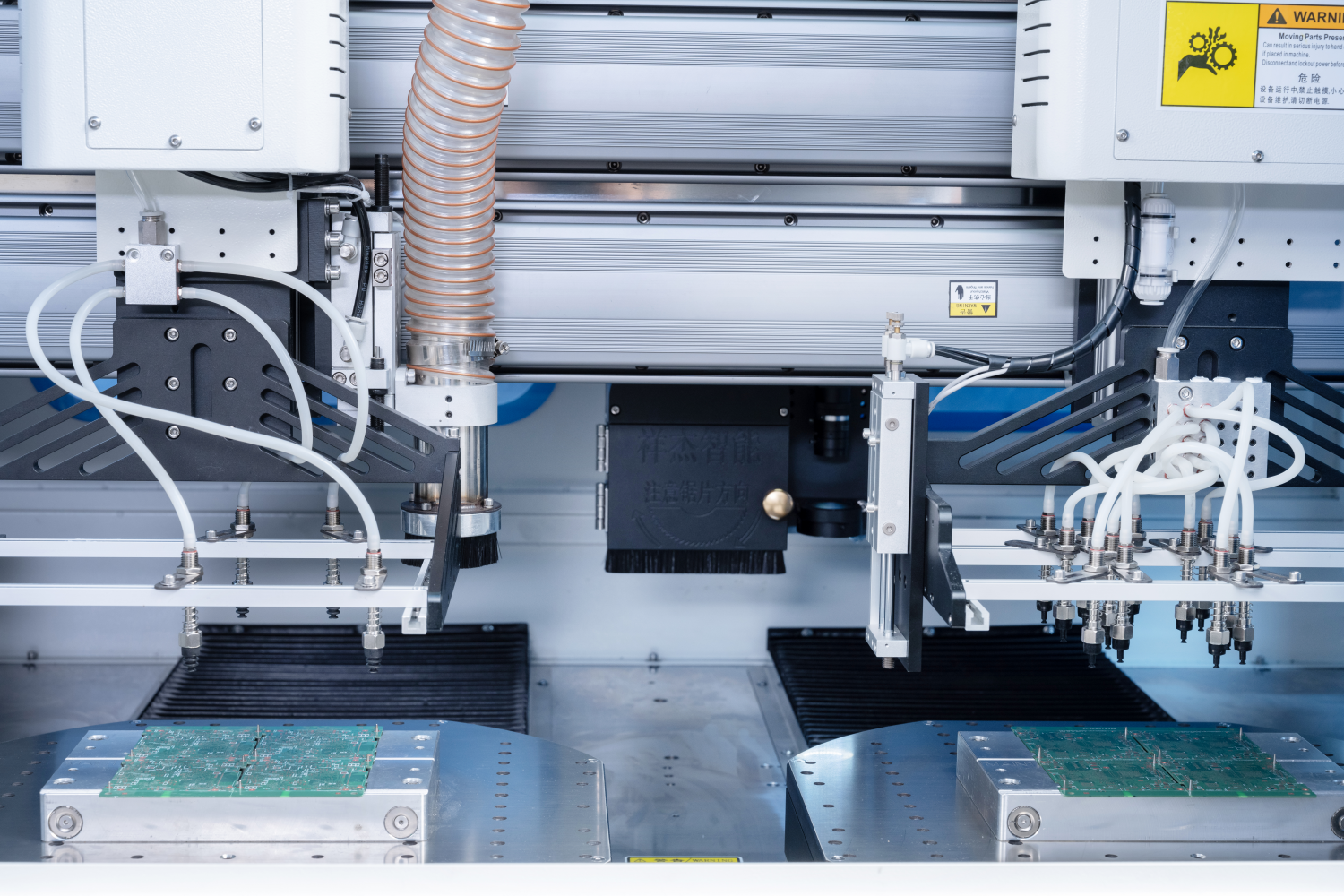

--Offline and online dual-purpose machine, track inflow, manipulator automatically grabs incoming materials and arranges the plate

--Using CCD vision automatic scanning, customized precision fixtures to ensure cutting accuracy

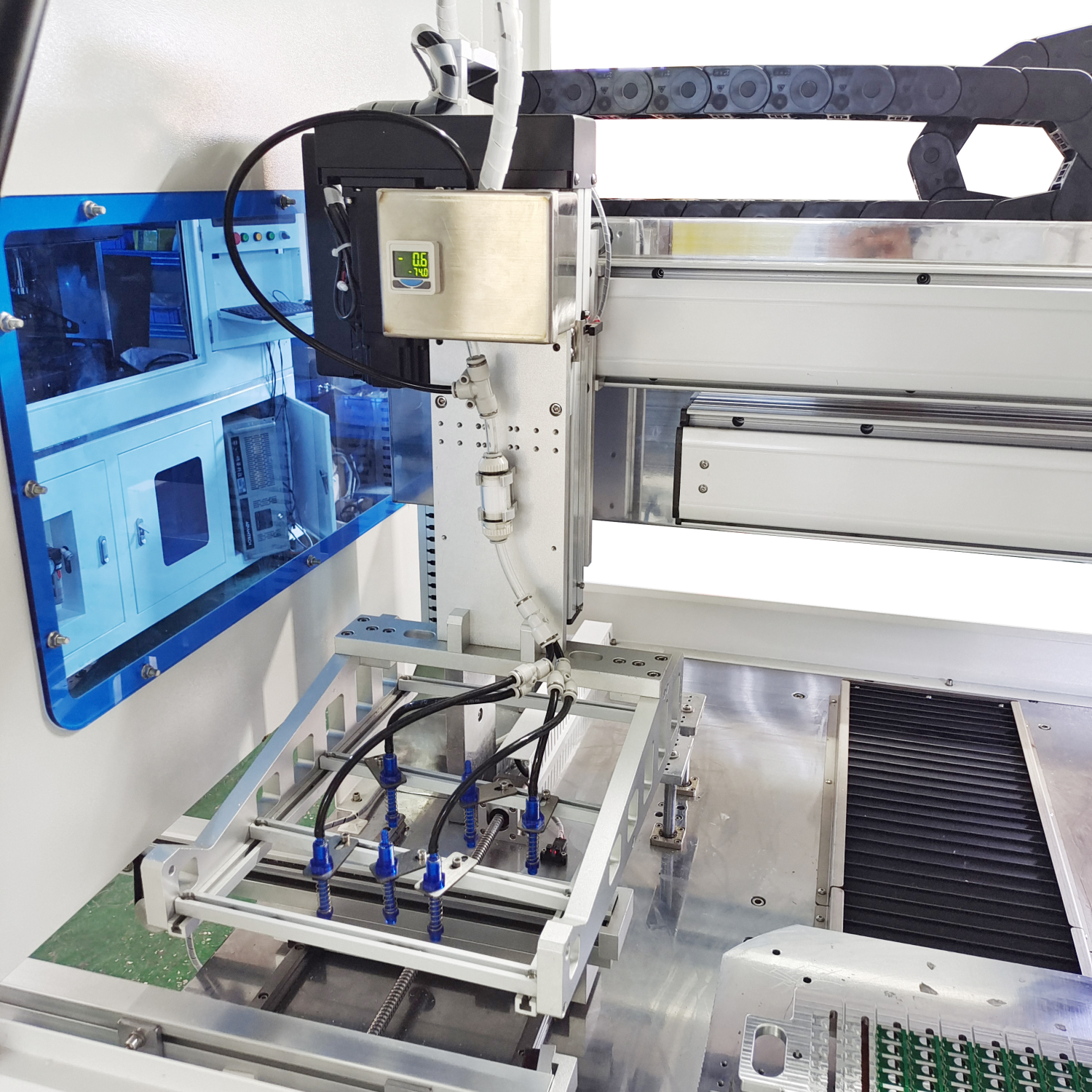

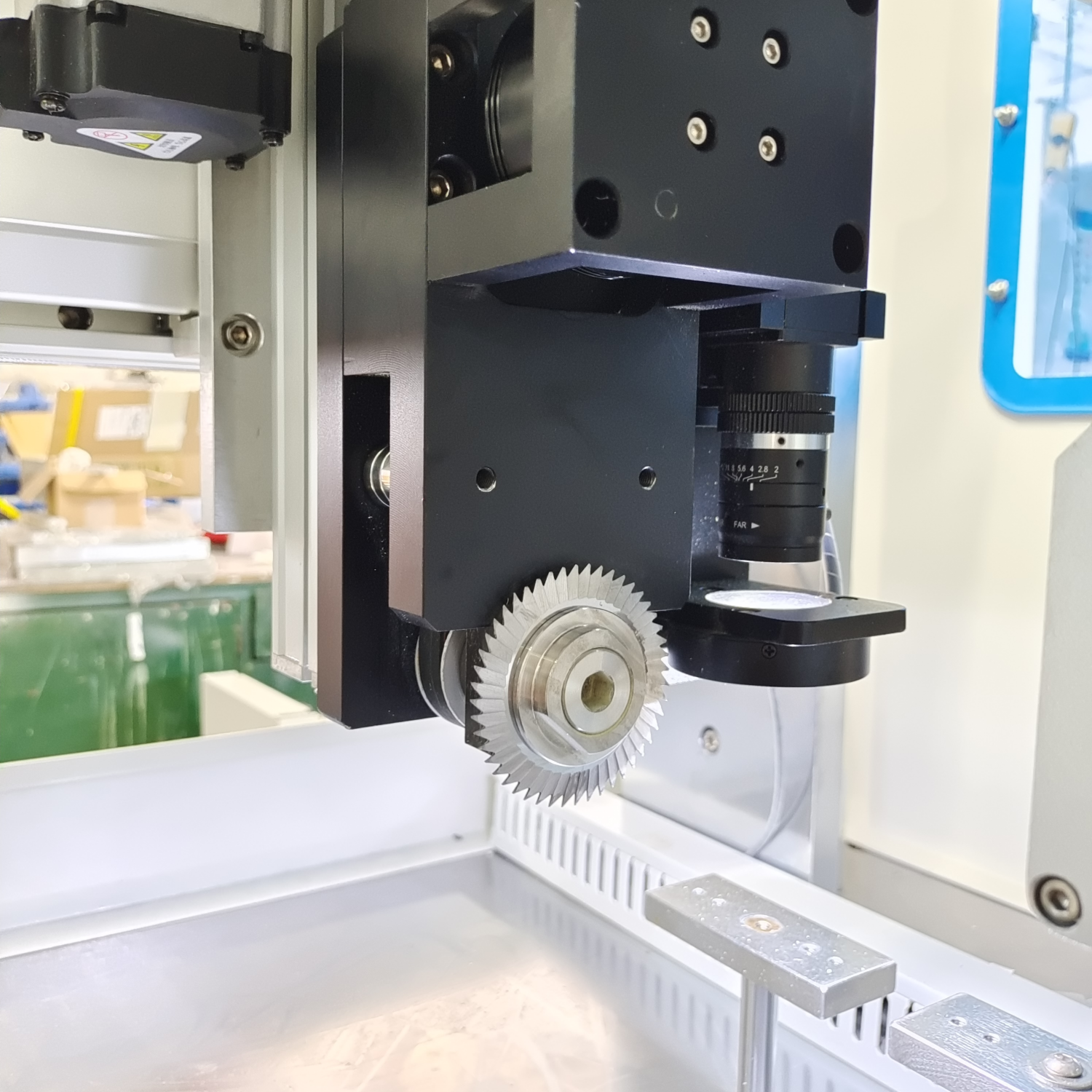

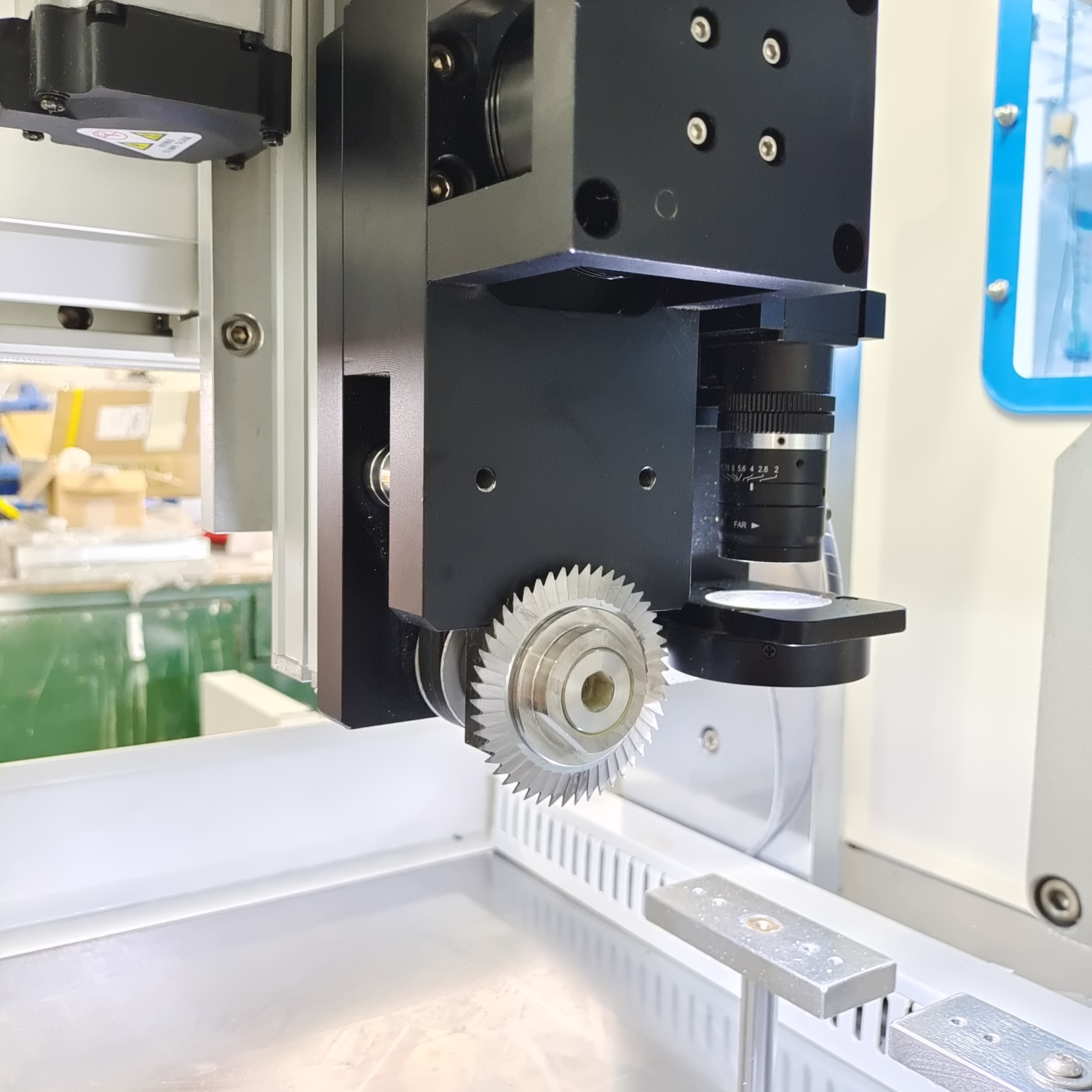

--Cutting with saw blades, suitable for all V-CUT boards, eliminating the trouble of constant cutting, faster and easier to change wires

--The cutting is thorn-free and the surface is smooth. The split plate stress is less than 300μe. Completely solve the problem of ordinary V-CUT board stress

--Equipped with a dust collector to collect dust synchronously during cutting

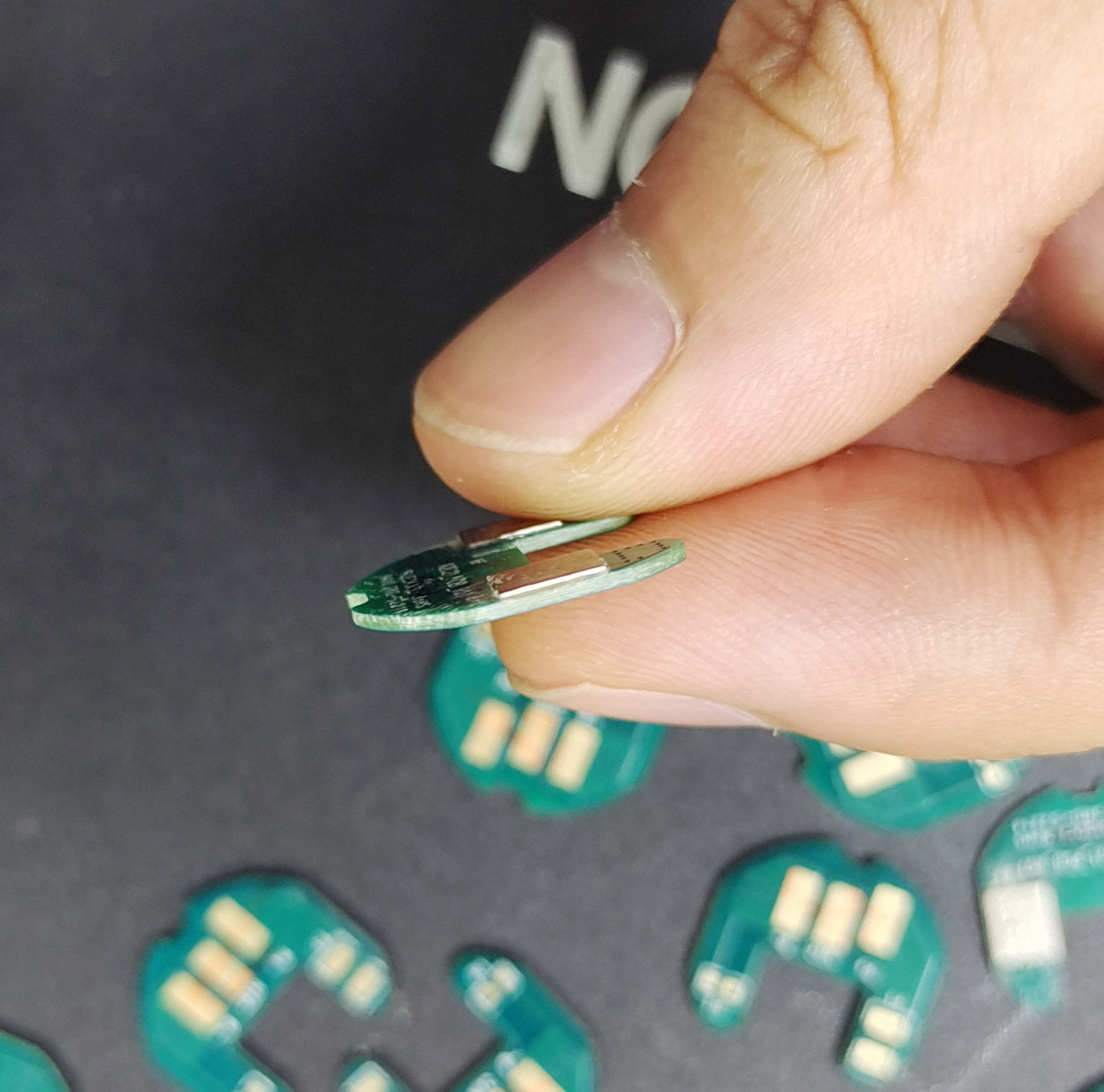

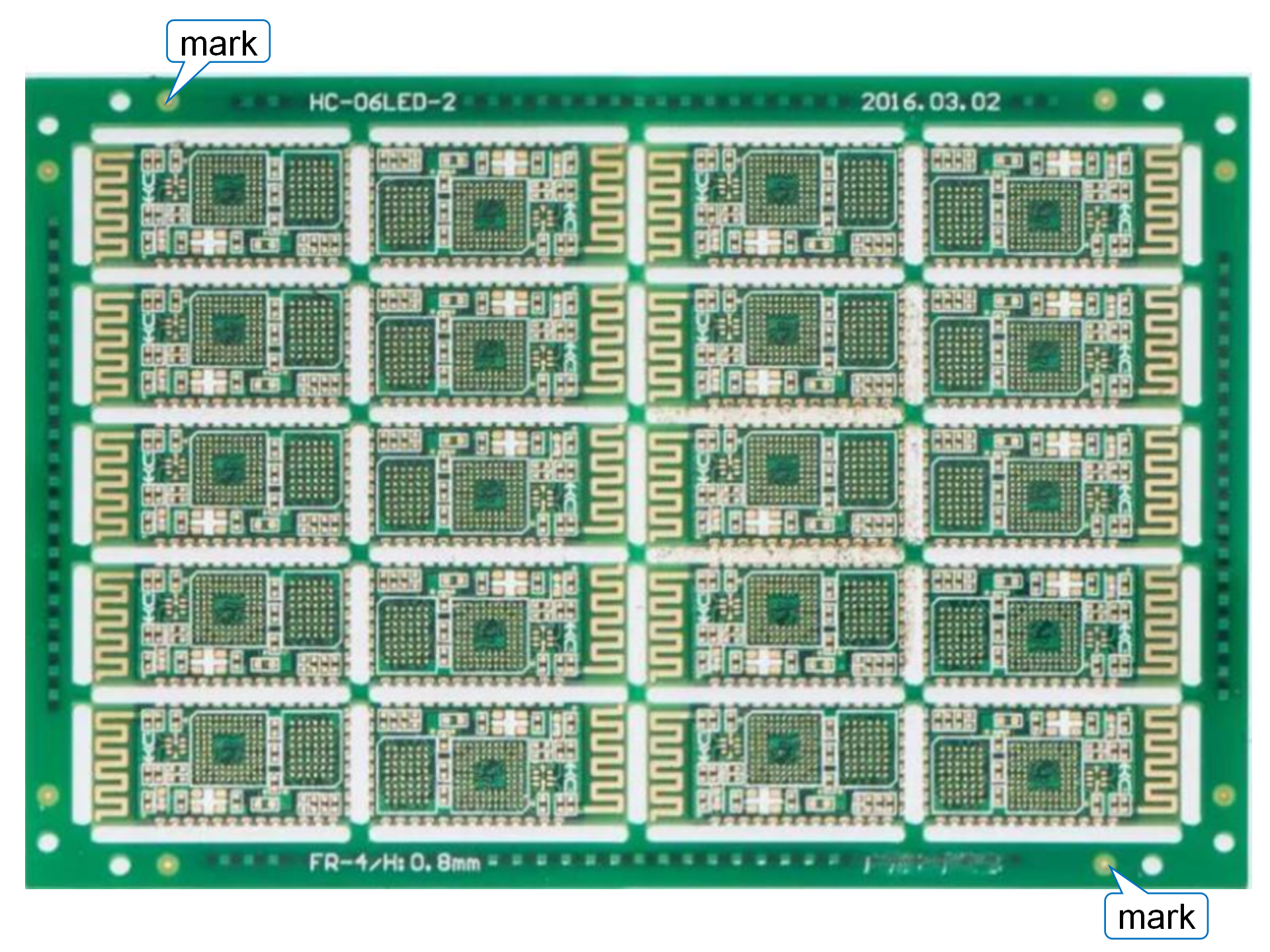

✧ Mark Positioning Correction System & Saw Blade

It can make line change and jig change more concise and precise, and can effectively prevent the board from not being placed in place during online production, or the product being cut due to mixing of materials. Since your company’s products may be processed on both sides, the standard mark point has only one side, so the correction action is indispensable, and the mark points that can be used are usually irregular in shape and shape; it is easy to report errors or offset offsets. According to the previous experience, our company has greatly improved the recognition pass rate and compensation accuracy by adopting the smart camera upgrade algorithm and special light source.

✧ Visual System

High pixel color digital camera and large magnification lens can assist program teaching and editing simulation functions. Automatic MARK positioning correction system.

Mark point correction principle

The position of the mark point of the PCB board and the connection point that needs to be cut is physically fixed. When editing the cutting path, after defining the mark point, the edited cutting path is bound to the relative position of the mark point. When the PCB board is biased, the position of the mark point will change with the PCB board. When the camera scans the mark point, it will automatically calculate the offset, and then compensate it in the cutting path.

✧ Product transfer platform

The dual-platform modular servo control system has extremely high stability, and the cutting accuracy can reach ±0.01mm, which can meet various cutting needs and ensure production quality.

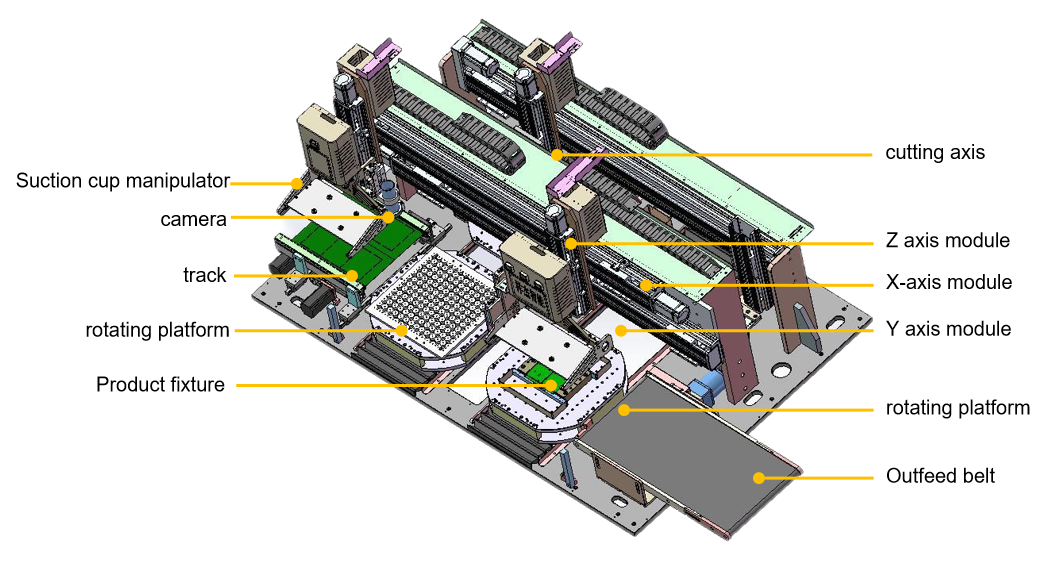

✧ Machine Structure

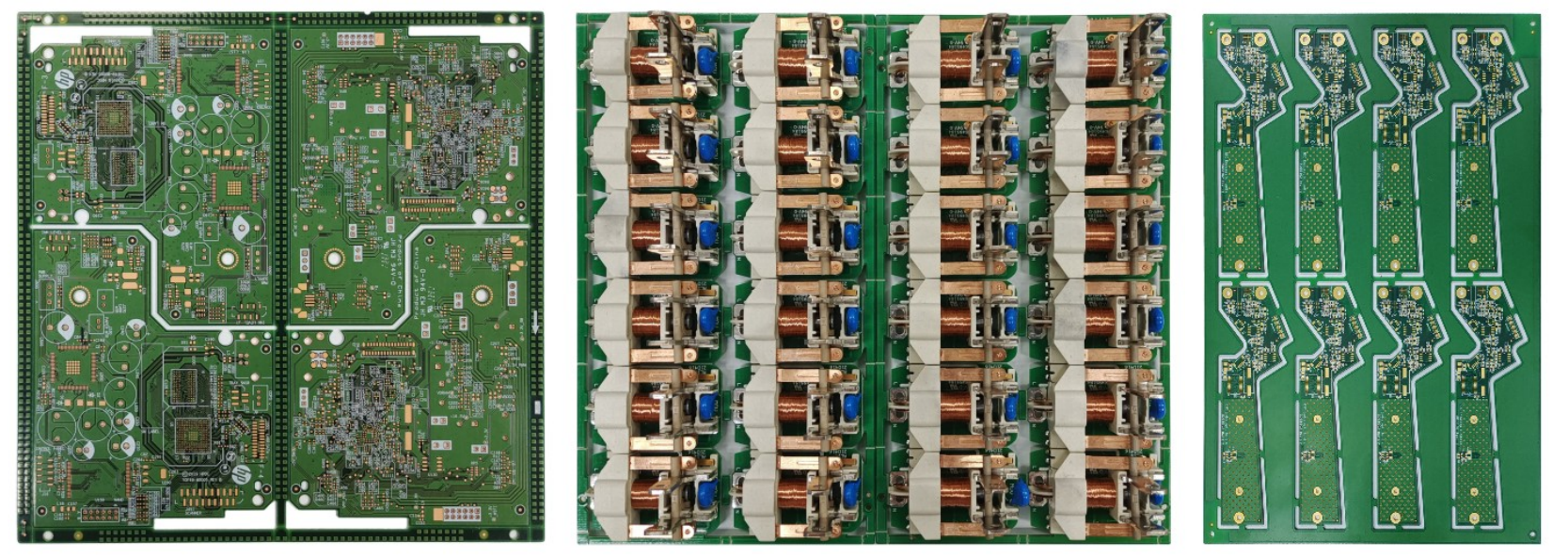

✧ Apply To

For cutting PCB circuit boards containing both V-grooves and point connections

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

✧ Company Information

✧ Exhibition

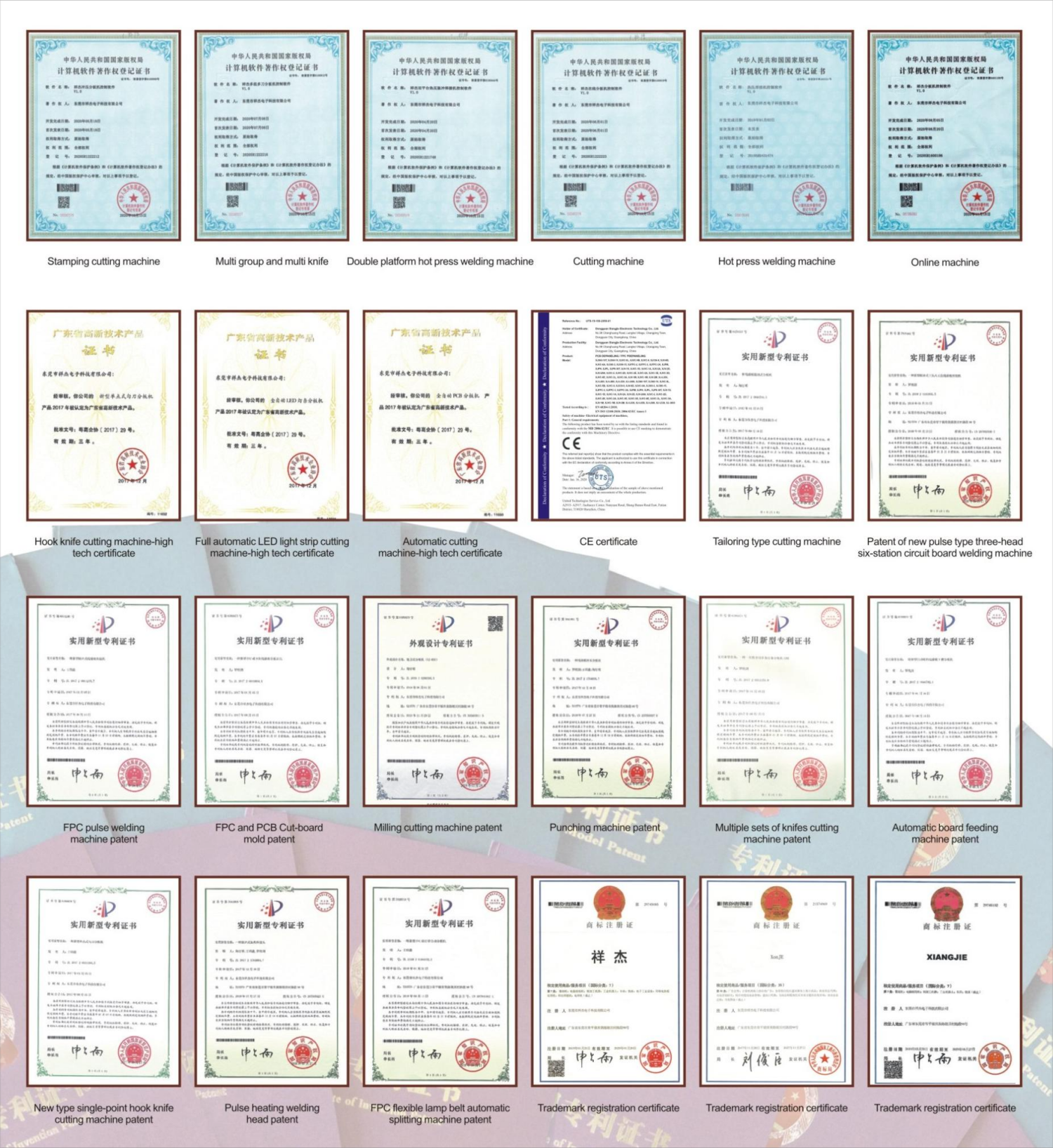

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

✧ FAQ