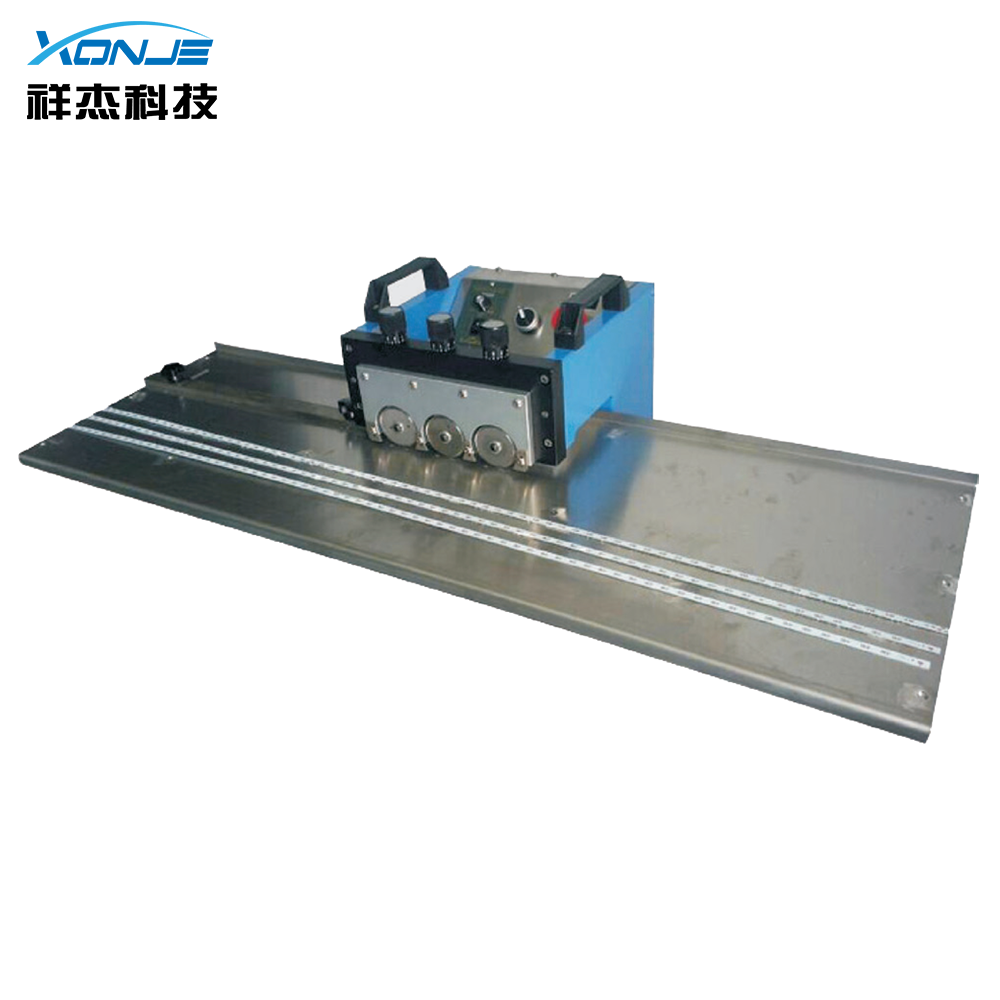

LED Light Strip Cutting Machine

✧ Features

1. The structure is simple and easy to use.

2. There are 3 blades on the upper and lower sides, the upper round knife is fixed during the cutting process, and the lower round knife rotates and cuts. The number of blades can be customized.

3.It can be used for Vcut with a narrow cutting pitch, with high efficiency and good segmentation quality.

4. According to the depth of the V groove and the tool wear, the distance between the upper round knife and the lower round knife can be adjusted accurately.

5. The slitting speed is controlled by the knob, and there are baffles installed on both sides of the round knife, which has high safety.

6. The round knife can be used for repeated grinding.

✧ Technical Parameter

A : > 0.25mm

B: 1.0mm(Max)

Standard cutter :

C2: ≧2mm C1: ≧0.3mm

Θ: ≧20°

| Maximum cut-board length | Unrestricted |

| Board splitting speed | 0-400mm/s |

| Board thickness | 0.6-3.5mm |

| Working voltage | 220V AC 500W |

| Machine weight | 45kg |

| Dimensions(L*W*H) | 1000*520*280MM |

| Added platform size(L*W*H) | 2400*520*280MM |

✧ Installation and Adjustment

1.Machine installation

(1) The machine can be carried by hand. (It is recommended that four people lift and move, and the stainless steel platform should not be used as a force during the carrying process)

(2) The table on which the machine is placed should be flat and stable

(3)Connected to power:Connect the 220VAC 50HZ power supply to the power socket

(4)Turn on the power, and the lower cutter rotates.

(5)Rotate the governor to change the speed.

(6)Switch the blade rotation to forward rotation,If there is a card board, it can be adjusted to the reverse direction and the substrate can be withdrawn

(7)In case of emergency, you can press the emergency stop button

3.Knife distance adjustment

Step 1: Loosen the adjustable handle in the picture below; turn it to the left to lock it and turn it to the right to release it. Note that it is to loosen, not remove.

With scale reference, it is easier to adjust the width

Step 2: As shown in the figure below, rotate the three scales to fine-tune the knobs, and the three cutters above can move vertically up and down to adjust the size of the upper and lower knife edges.

✧ Cutter Distance Adjustment Standard

(1) First of all, let’s talk about the cutting principle of the equipment: this machine adopts the method of multiple cutting, and the cutting of the circuit board is completed by six circular knives, and the upper and lower two pieces are grouped together to form a cutting unit, with a total of three groups. The whole cutting process is divided into three stages, the first set of blades cuts 40% of the circuit board first, then the second set of blades completes 40% of the cutting volume, and the last set of blades separates the product and completes the job.

(2) Therefore, it is recommended to adjust the cutter distance in the following ways:

1.The first group of cutter blades can be adjusted to a state of non-connection.

2.The adjustment of the second group of cutting knives is the same as that of the first group of cutting knives. (In the actual cutting process, the second group of cutting knives can be adjusted a little more downward than the first group)

3.The third group of cutting knives can be adjusted to have a little overlap between the two knives, as shown in the figure below:

Strain test of Multi-round Knife Cutting Machine

The gap between the two knives is just close

The two knives overlap by about 0.1mm

Attention:

The above adjustment process is to prevent the knife edge from cracking when the adjustment amount is too large at one time. It can be adjusted a little at a time, and the sample can be cut for trial cutting. If it cannot be cut, make a second adjustment until the product is cut. Turn on the power switch to keep the machine in working condition

(3) Before adjusting the distance between the upper and lower blades, loosen the adjustable handle at the back, otherwise it cannot be adjusted; after the adjustment, the adjustable handle must be locked, otherwise the machine will not be able to cut normally.

✧ Adjustment of the width of the cut-board

Step 1: For the light bar with a board edge, when adjusting the width of the board, the board edge should be cut off as shown in the figure below. (The light bar without board edge skips this step)

Step 2: Loosen the two knob screws on the stainless steel platform in the picture below.

Step 3: Push the aluminum base plate by hand to let the blade move forward along the V groove to the third set of blades

As shown in the picture below: Push the adjustable baffle to the edge of the board and bring the two closer together. Then tighten the two knob screws on the adjustable baffle.

✧ Repair and Maintenance

1.Upper Knife Replacement:

(1) Loosen the three adjustable handles on the back of the machine and turn the scale fine-tuning knob to raise the upper knife

(2) Insert a 3mm hexagon key into the anti-rotation hole of the blade; use a 4mm hexagon key to unscrew the M5 screw in the middle; take out the spacer and the blade, and replace it with a new round cutter in sequence.

2.Replacing the lower cutter:

(1) Remove the upper cutter, and remove the knife guards on both sides of the upper cutter. As shown in the figure below:

(2) Use a hex key to remove the lower cutter guard, as shown in the picture below:

(3) The replacement method of the lower knife and the upper knife is the same, and the lower knife is replaced.

3.Knife grinding:

(1) Generally speaking, the cutter can be reground 2~3 times.

4.Rust Prevention and Lubrication:

(1) The machine should be stored in the upper and lower cutters with anti-rust oil.

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

✧ Company Information

Xiangjie Technology,founded in 2008, headquartered in Dongguan witch is the world's manufacturing capital. It is a supplier focusing on PCB circuit board cutting and soldering solutions, and is committed to providing standardized high-quality equipment and customized services to global users. After more than ten years of innovation and development, especially in the field of PCB cutting, Xiangjie Technology has become a leading manufacturer of SMT peripheral equipment in China and a world-renowned manufacturer. With a strong innovative R&D team and strong sales and after-sales service capabilities, it has served more than 30 countries and regions.

✧ Exhibition

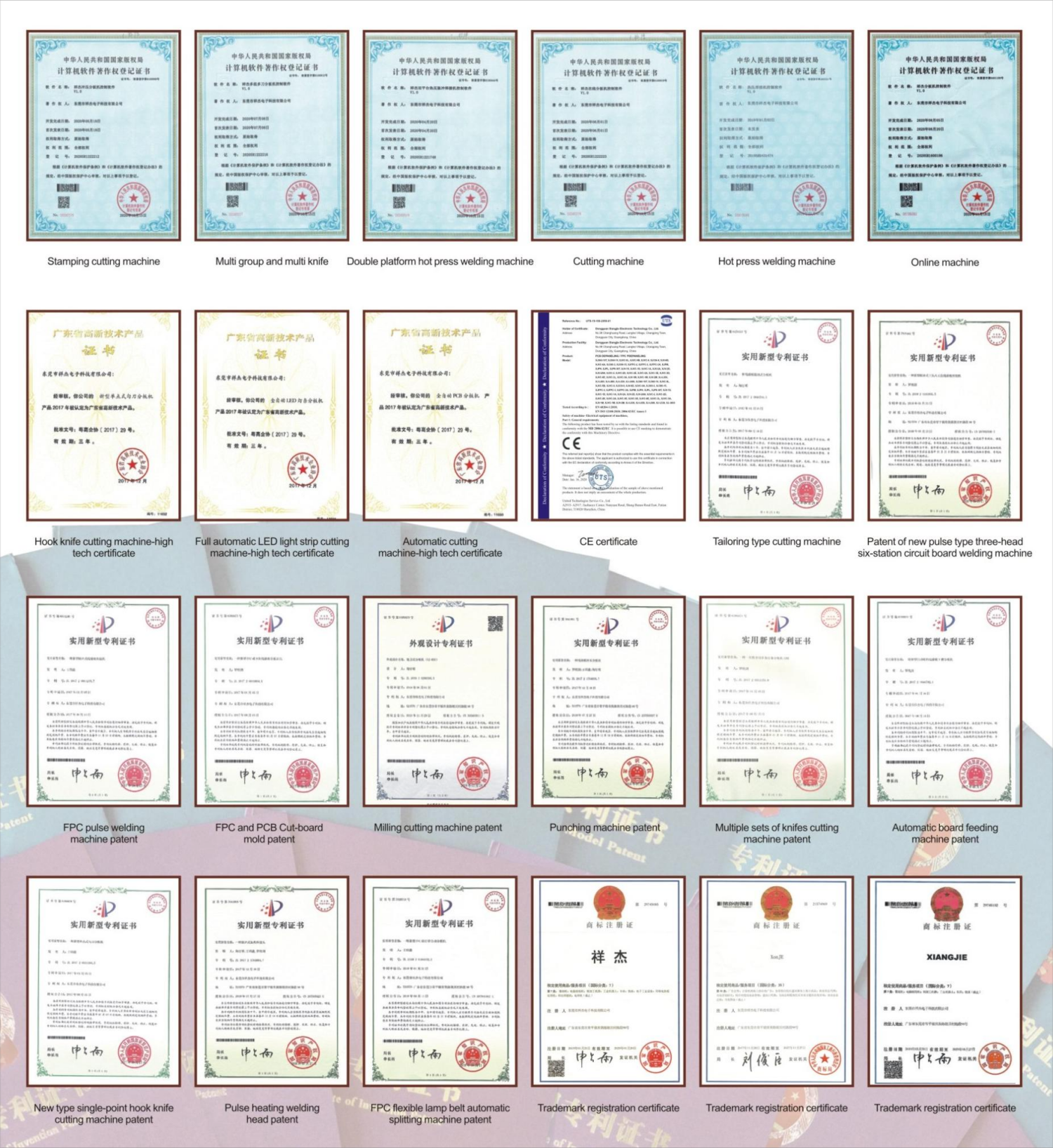

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

✧ FAQ

Q: What we can do for you?

A: Professional SMT peripheral equipment supplier; With more than ten years of mature industry experience

Q: Are you a trade company or manufacturer?

A: We are manufacturer with complete processing equipment

Q: What is your delivery date?

A: About 35 days after receipt of payment.

Q: What is your payment terms?

A: 100% balance before shipment.

Q: What your main customers?

A: PCB assembly manufacturer, SMT equipment manufacturer, light strip manufacturer, etc..

Q: Why choose you?

A: Leading SMT Supplier in China;

Trade assurance to USD 560,000+; Professional after-sales service team.