Multi-group Multi-knife Automatic Splitting Machine

✧ Features

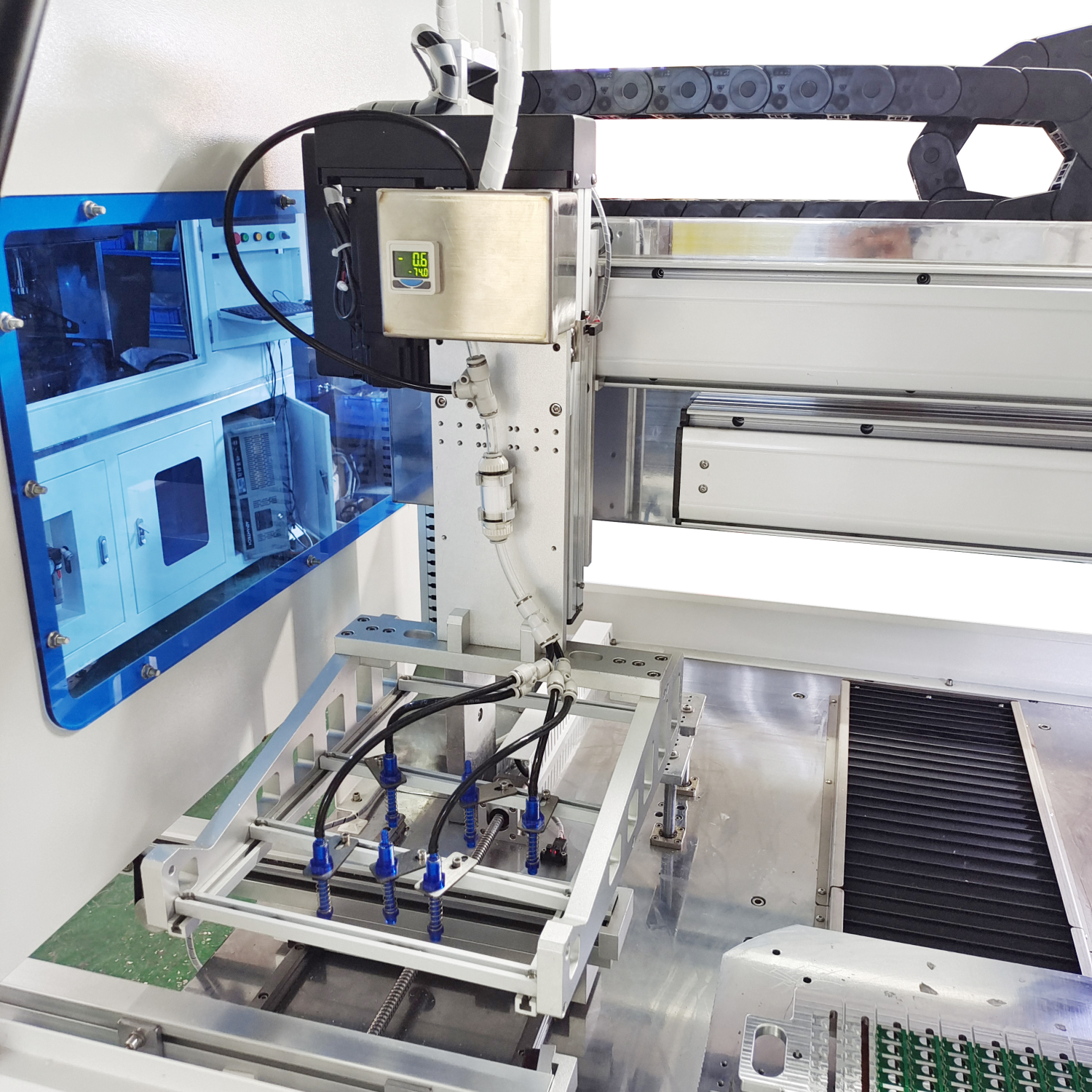

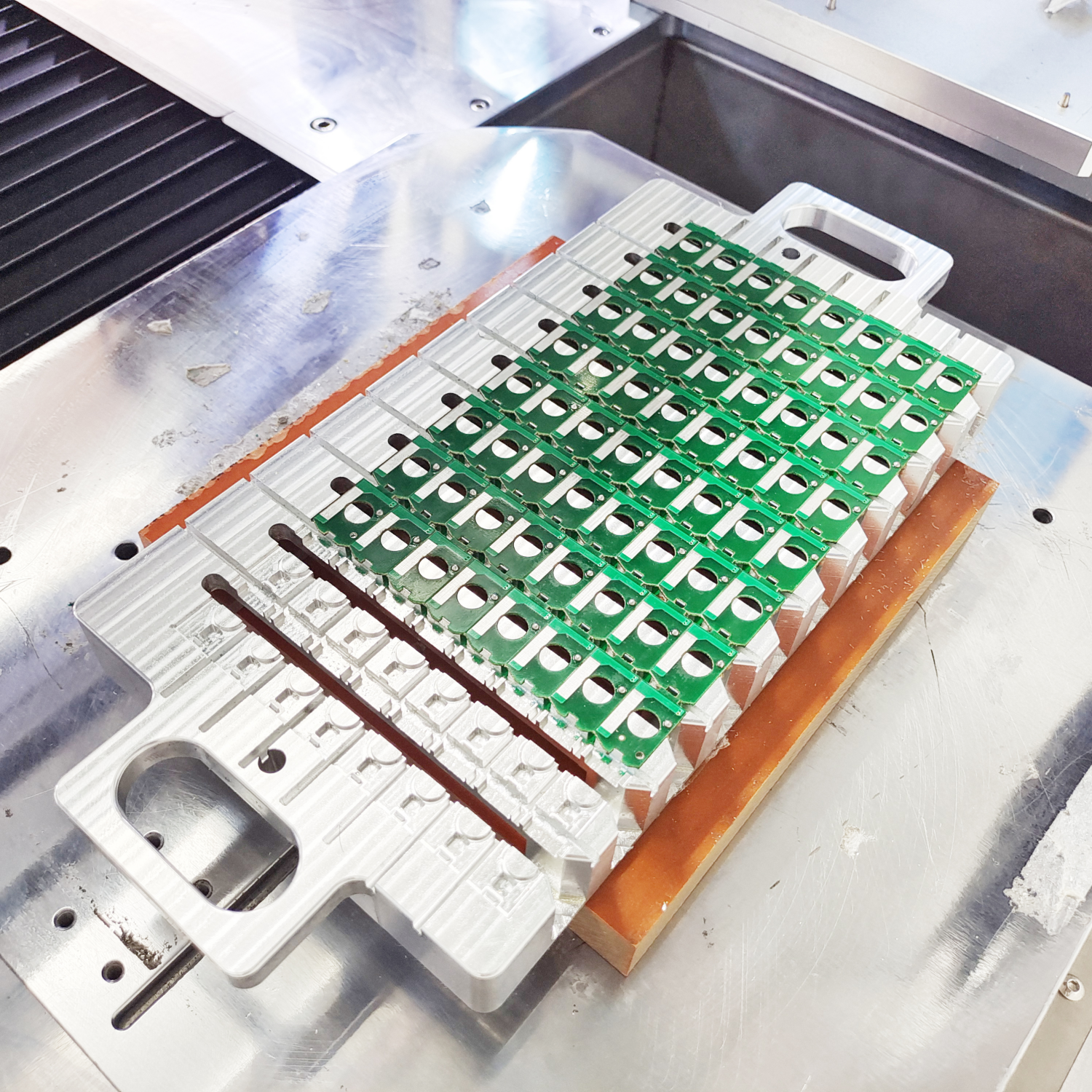

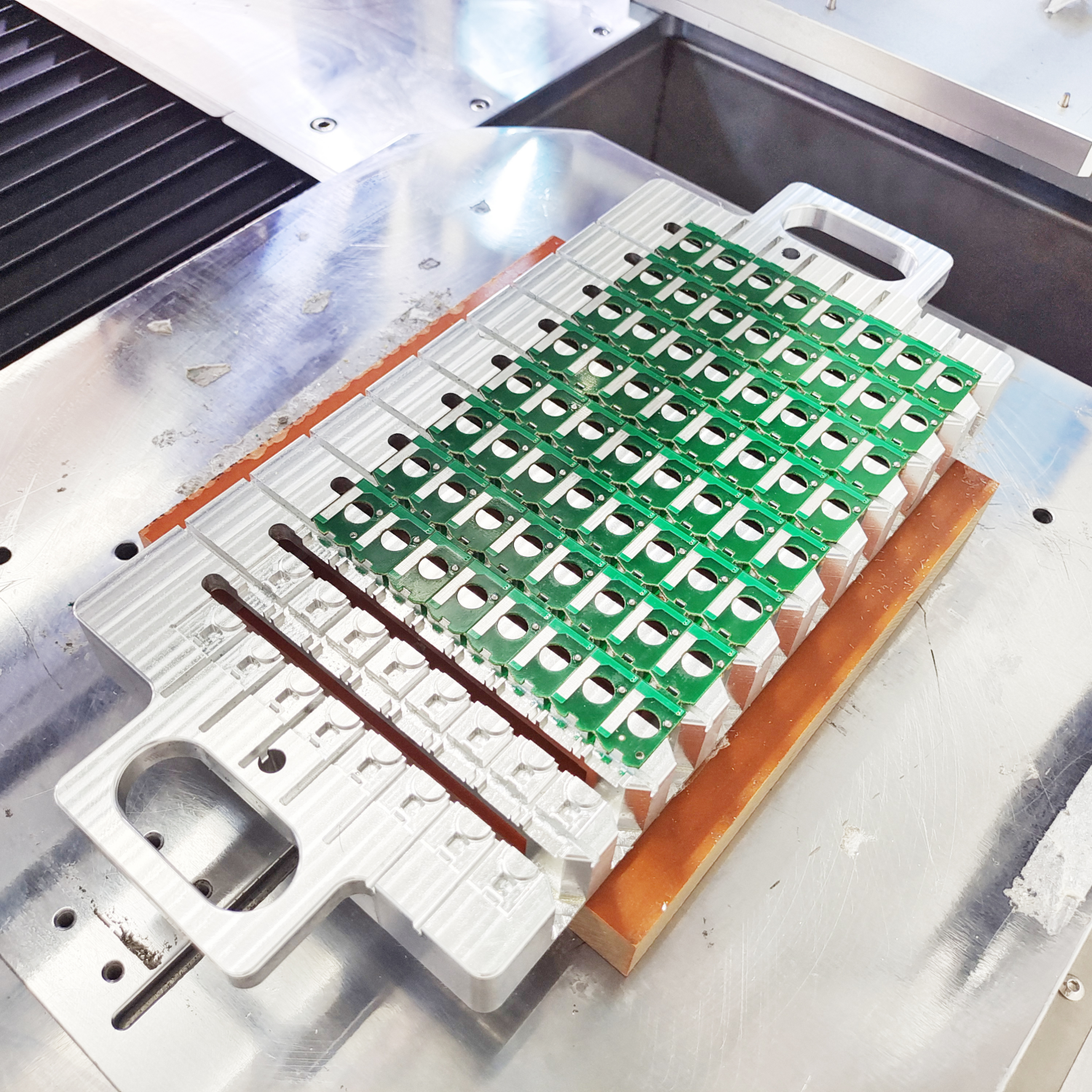

The fully automatic multi-blade splitting model V slot splitting machine further improves the splitting quality; for cutting aluminum substrates (300-1500MM), copper substrates, FR4, and fiberglass boards, they are clean and free of burrs., The splitting machine can be connected to the assembly line to realize automatic splitting without manual placement; the split and cut boards are transported away through the assembly line, which greatly saves manpower. When changing the product, you can directly exchange the die part without manual adjustment of the knife, which greatly saves time.

1 .The equipment is used for multi-group and multi-knife automatic board splitting, and the lamp strip machine with a width of more than 10MM can be quickly changed, and the whole board can be divided at one time, which is more than 20 times the efficiency of the traditional splitting machine;

2. The electrical control part can be selected in the man-machine interface, which is convenient to open or shield;

3. Human-computer interface, light curtain form and acrylic cover are used on the table to ensure safety;

4. There is a dust collecting tray under the splitting knife mold (a dust collector can be installed according to customer requirements);

5. Floor-standing structure is adopted as a whole;

6. The frame of the automatic line equipment adopting square steel welded frame,sheet metal sealing plate.surface baked steel paint;

7. The work surface of the equipment is made of 45# steel plate or AL6061 aluminum plate, and the surface is plated/oxidized;

8. Cutting material: fiberboard, aluminum substrate, copper substrate;

9. Tool life: more than 500,000 times;

10. Data monitoring system: boot time monitoring, capacity monitoring, equipment failure information and automatic rejection system, etc.

✧ Technical Parameter

| Model | XJVC-5LA | XJVC-5LB | XJVC-5LC |

| Number of knife sets | lset | 2sets | 3sets |

| Maximum cut-board length |

Unrestricted |

||

| Board splitting speed |

0-400mm/s |

||

| Board thickness |

1.0-3.5mm |

||

| Service voltage |

220V |

||

| Machine weight | 160kg | 195kg | 195kg |

| Dimensions(L*W*H) | 1180*500*1200MM | 1300*600*1200MM | 1300*600*1200MM |

| Dimensions of conveyor bett(L*W*H) | 1300*600*1200MM | 1300*600*1200MM | |

✧ Equipment Introduction

--Optional operating system, dual development of windows and Linux operating systems, approved by Huawei. Safer and more open

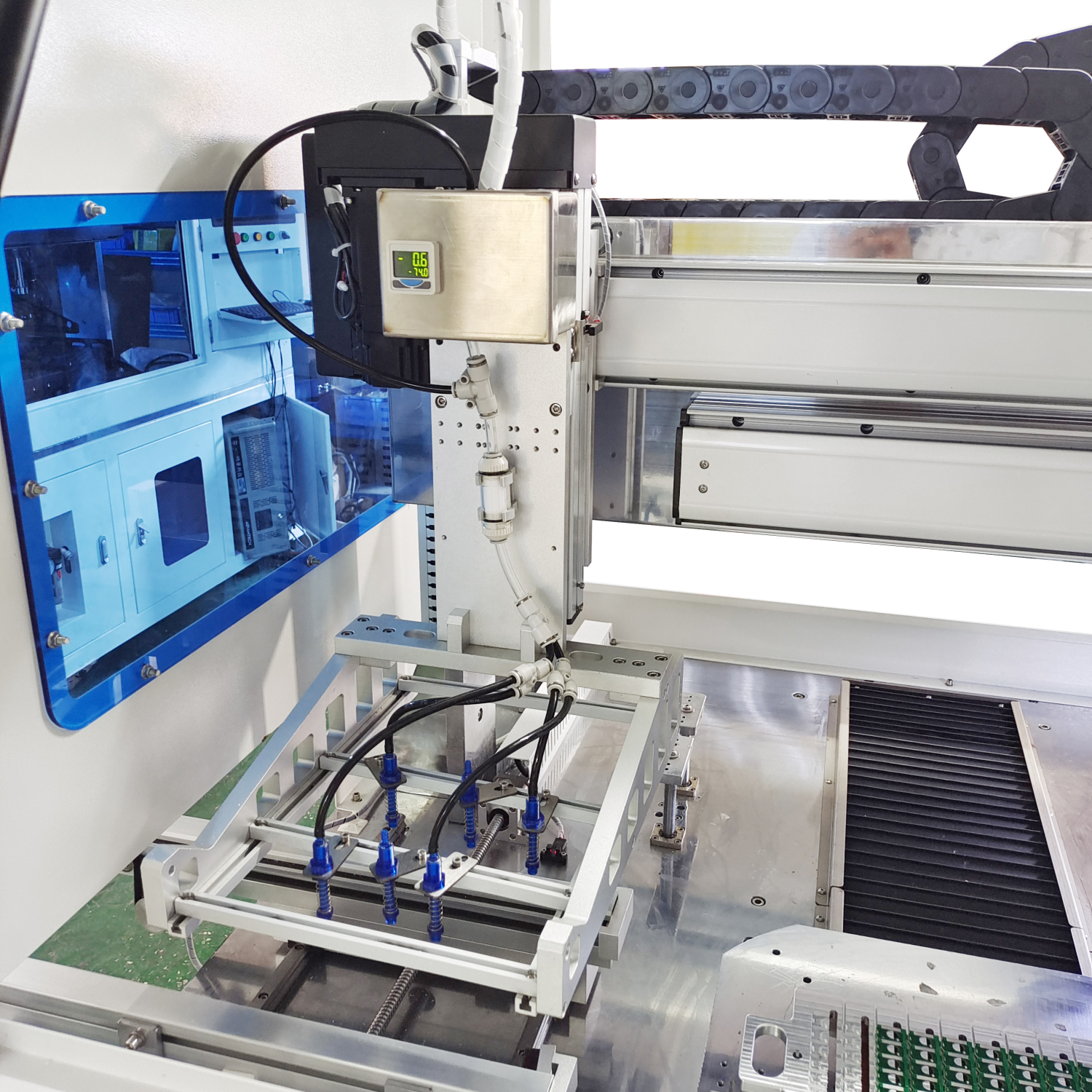

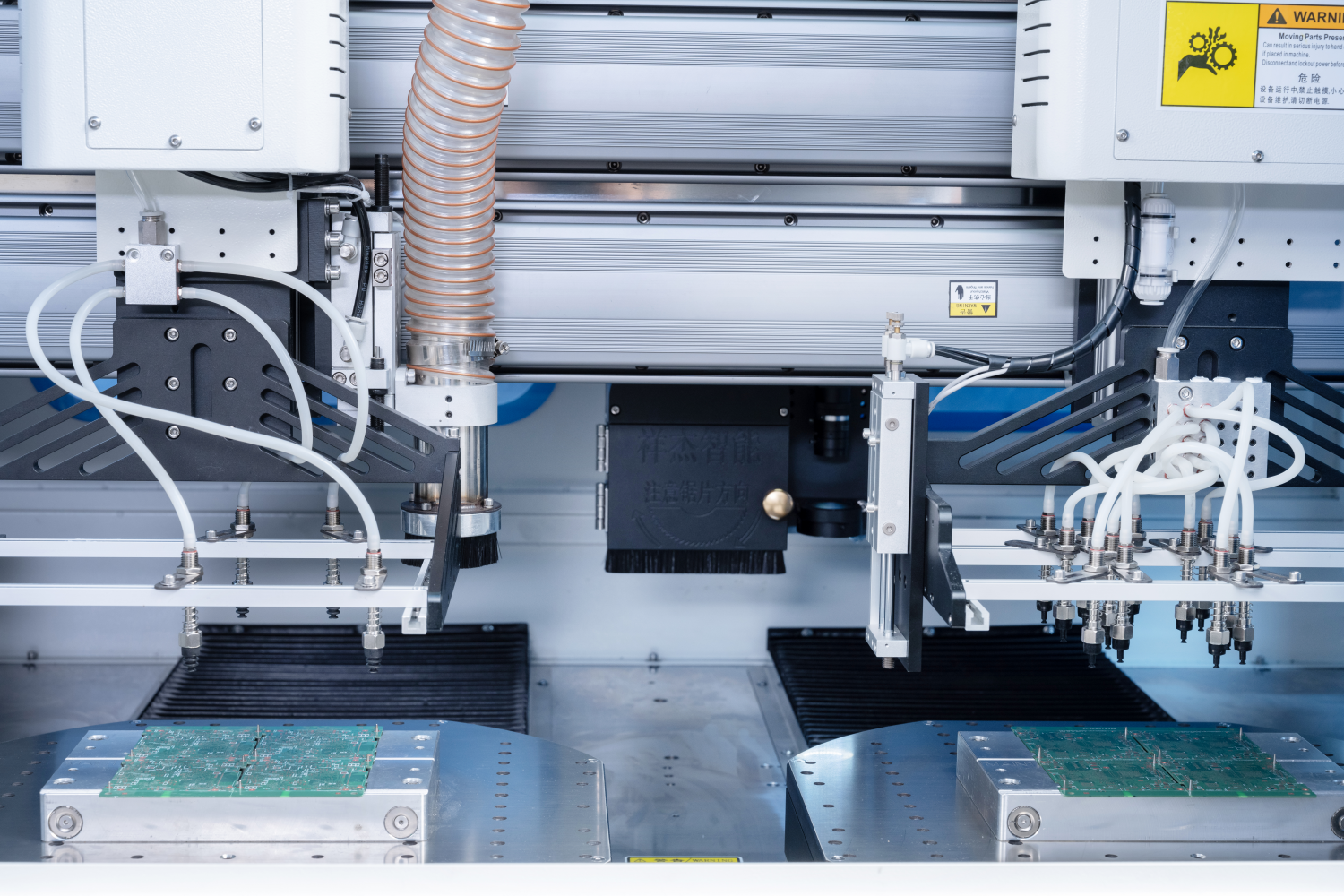

--Offline and online dual-purpose machine, track inflow, manipulator automatically grabs incoming materials and arranges the plate

--Using CCD vision automatic scanning, customized precision fixtures to ensure cutting accuracy

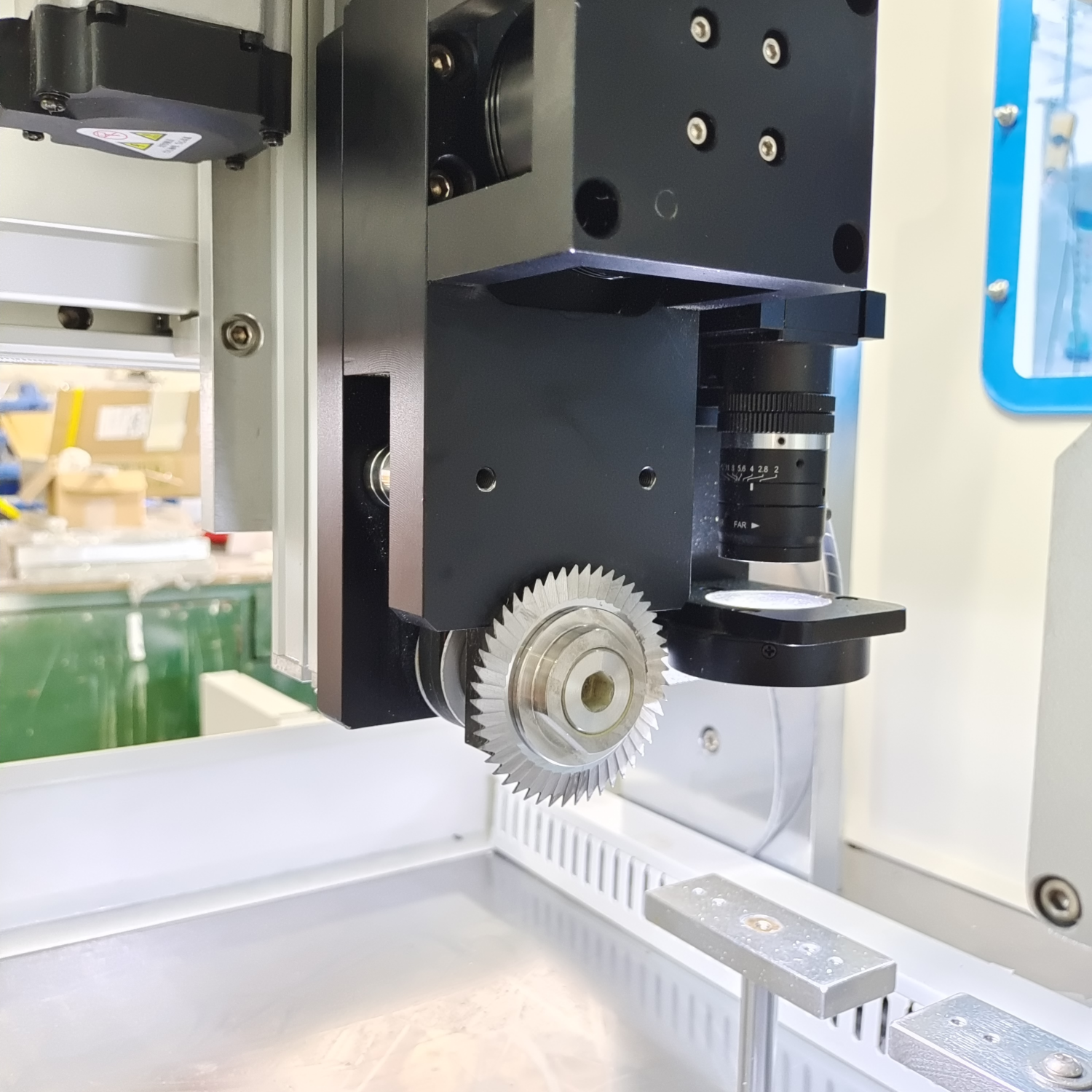

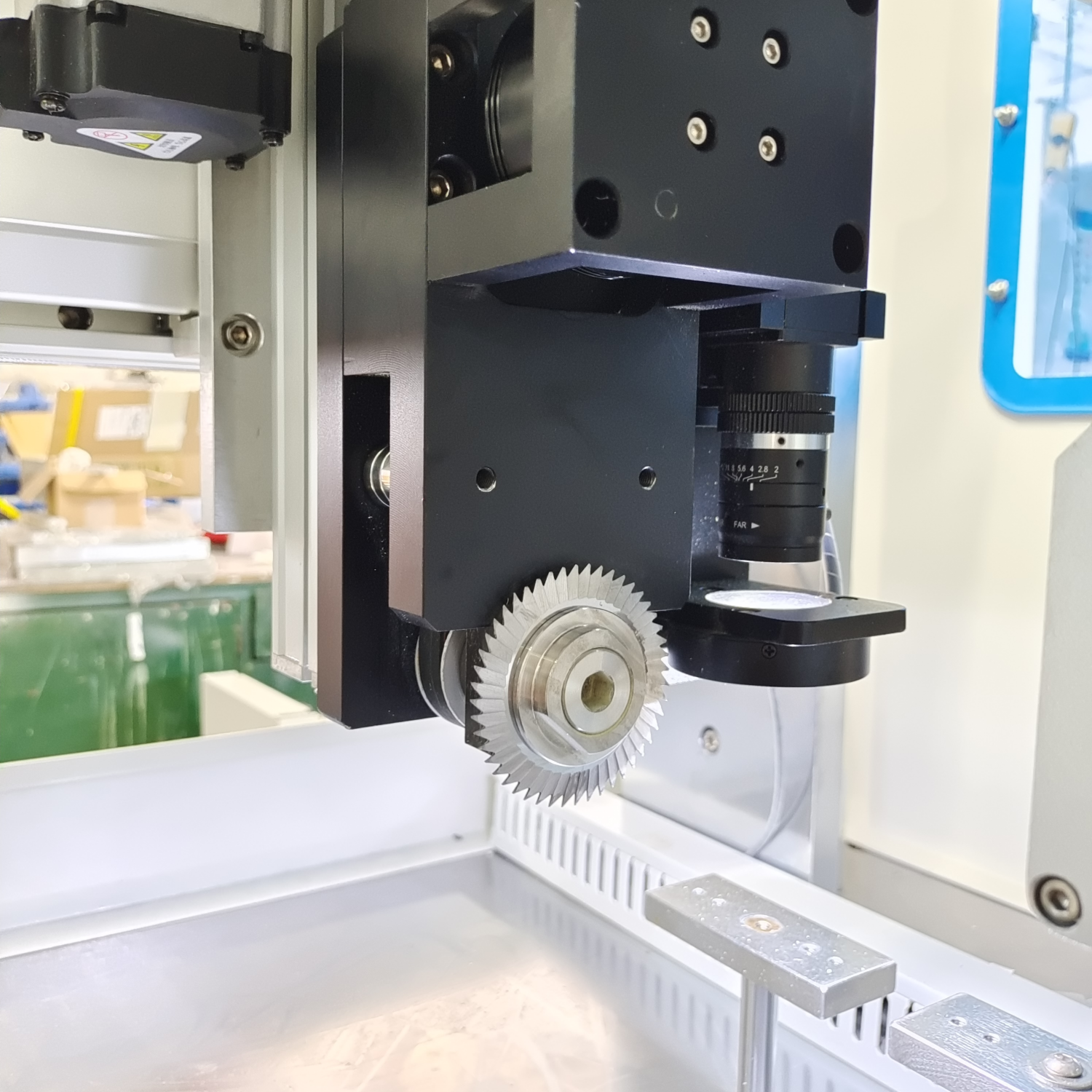

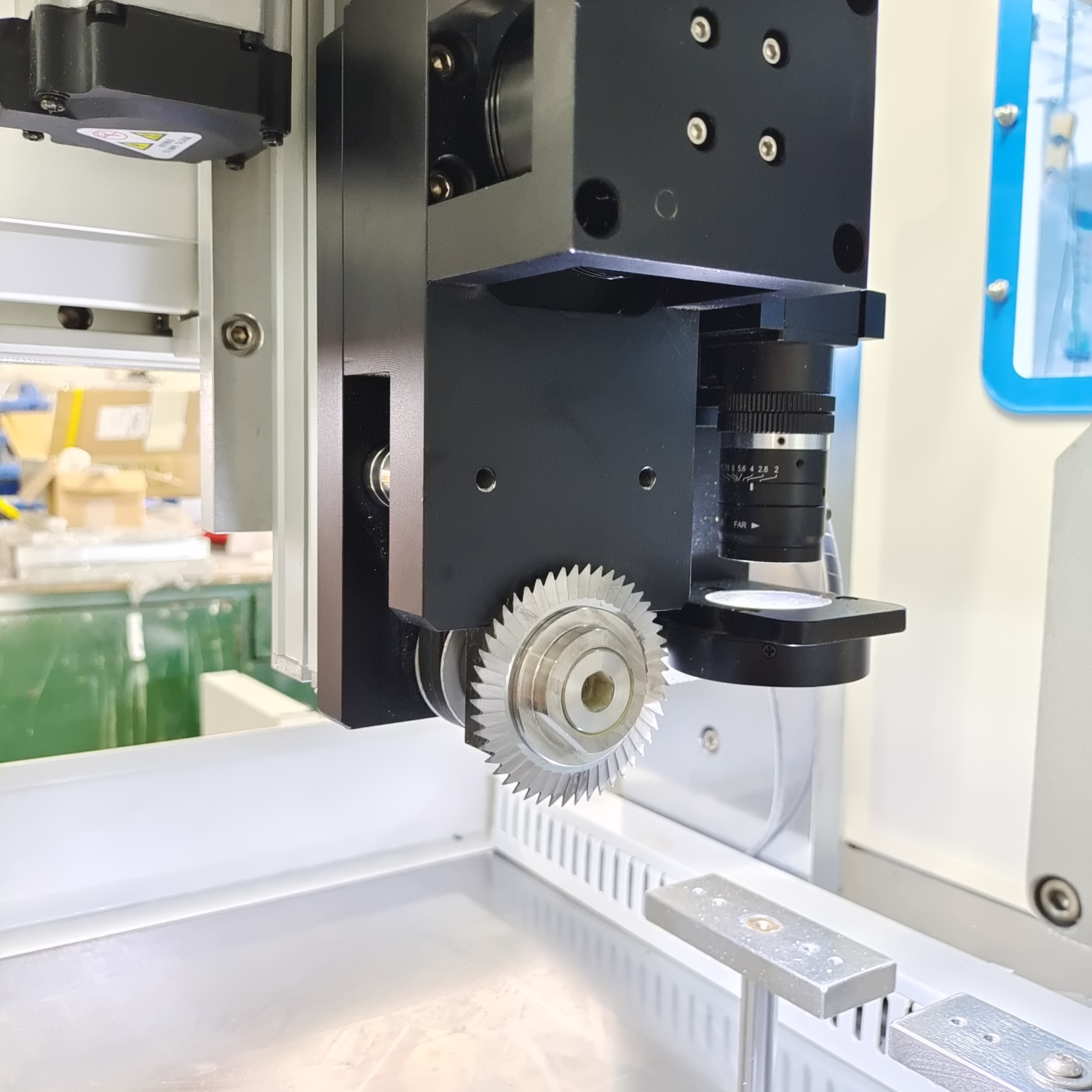

--Cutting with saw blades, suitable for all V-CUT boards, eliminating the trouble of constant cutting, faster and easier to change wires

--The cutting is thorn-free and the surface is smooth. The split plate stress is less than 300μe. Completely solve the problem of ordinary V-CUT board stress

--Equipped with a dust collector to collect dust synchronously during cutting

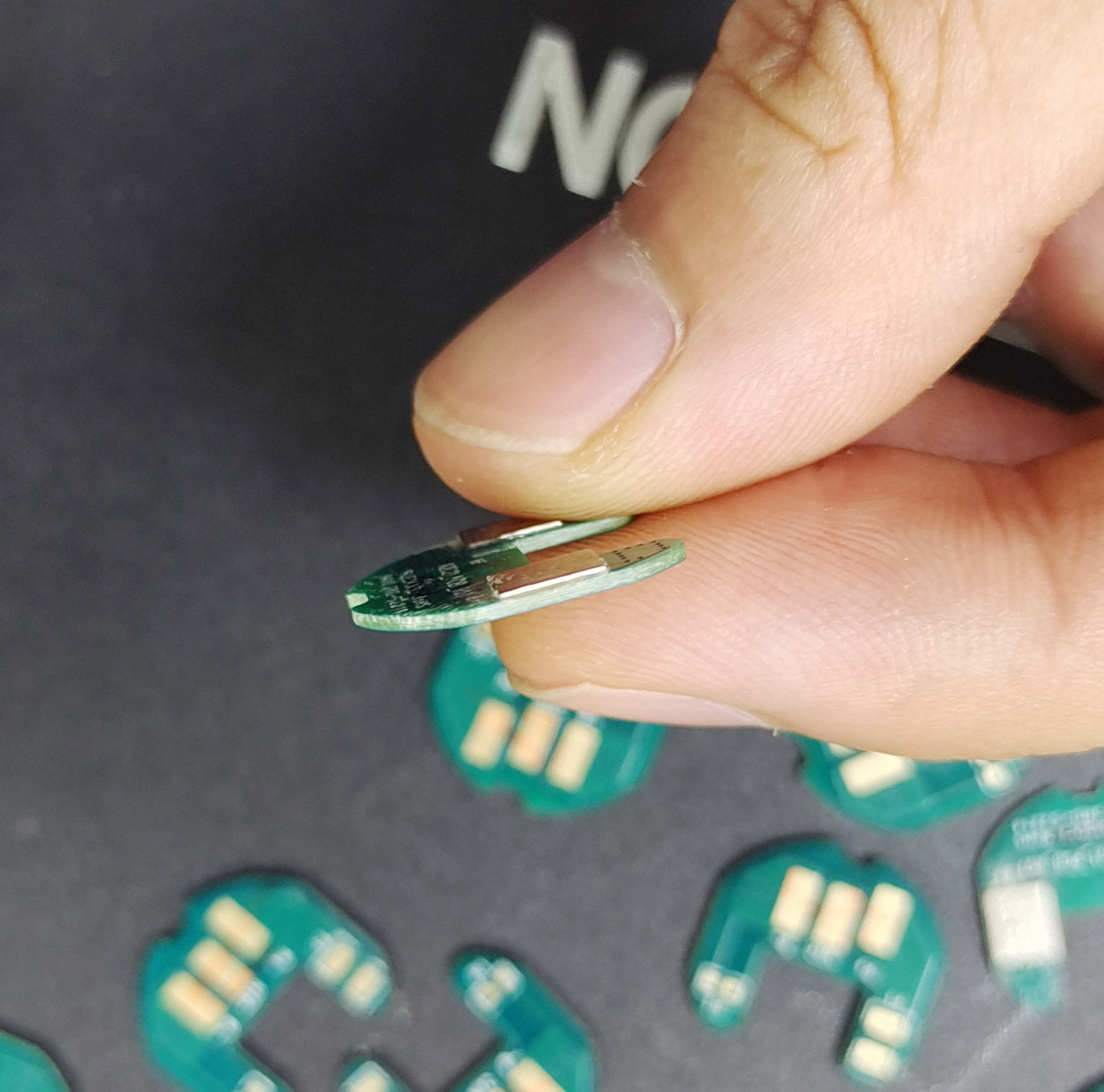

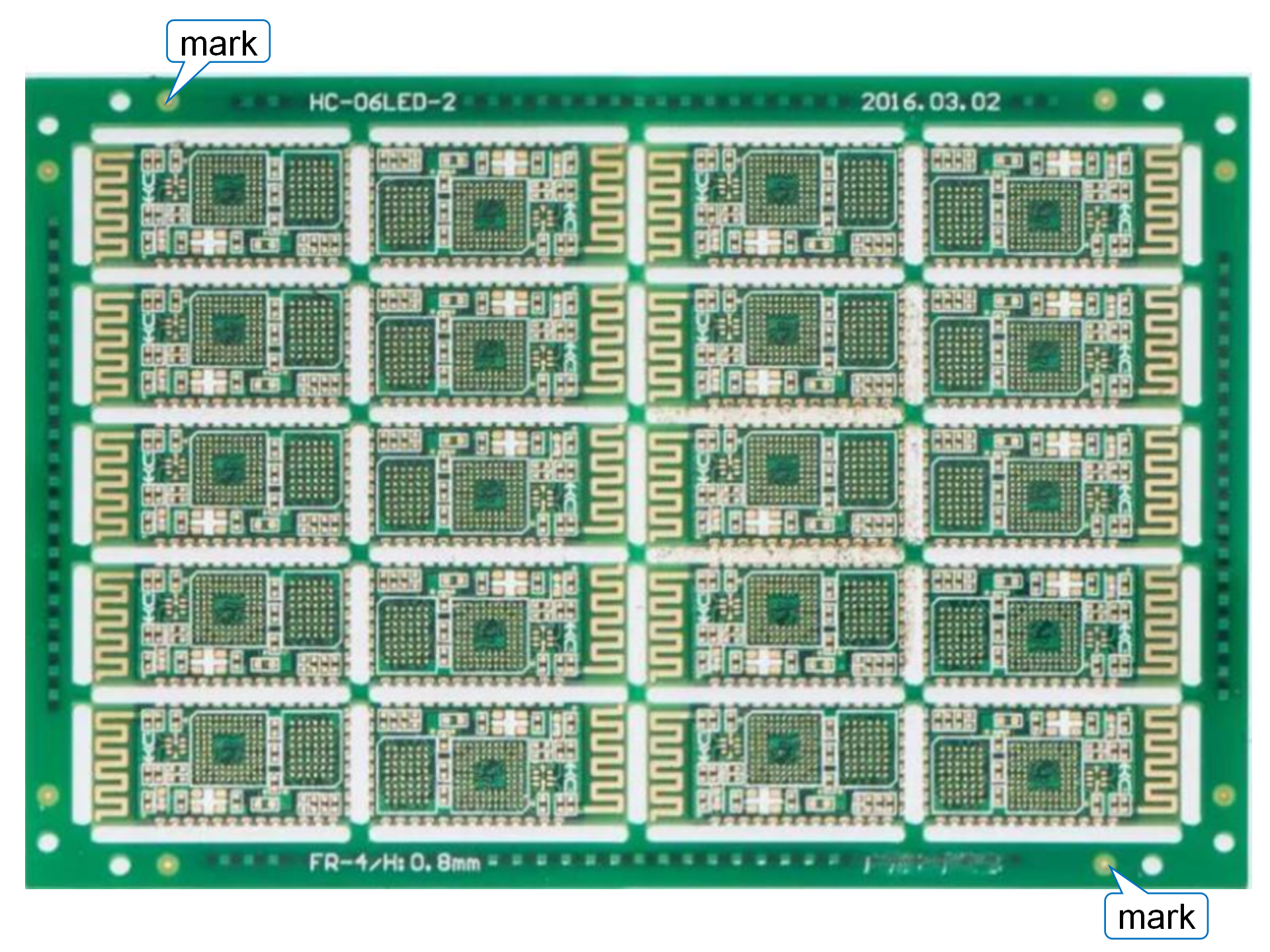

✧ Mark Positioning Correction System & Saw Blade

It can make line change and jig change more concise and precise, and can effectively prevent the board from not being placed in place during online production, or the product being cut due to mixing of materials. Since your company’s products may be processed on both sides, the standard mark point has only one side, so the correction action is indispensable, and the mark points that can be used are usually irregular in shape and shape; it is easy to report errors or offset offsets. According to the previous experience, our company has greatly improved the recognition pass rate and compensation accuracy by adopting the smart camera upgrade algorithm and special light source.

✧ Visual System

High pixel color digital camera and large magnification lens can assist program teaching and editing simulation functions. Automatic MARK positioning correction system.

Mark point correction principle

The position of the mark point of the PCB board and the connection point that needs to be cut is physically fixed. When editing the cutting path, after defining the mark point, the edited cutting path is bound to the relative position of the mark point. When the PCB board is biased, the position of the mark point will change with the PCB board. When the camera scans the mark point, it will automatically calculate the offset, and then compensate it in the cutting path.

✧ Product Transfer Platform

The dual-platform modular servo control system has extremely high stability, and the cutting accuracy can reach ±0.01mm, which can meet various cutting needs and ensure production quality.

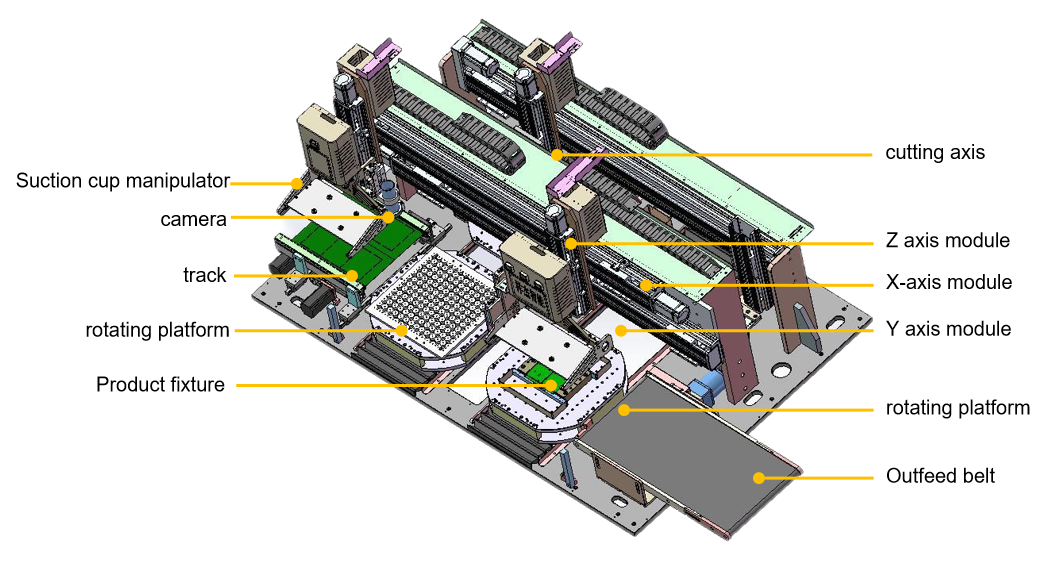

✧ Machine Structure

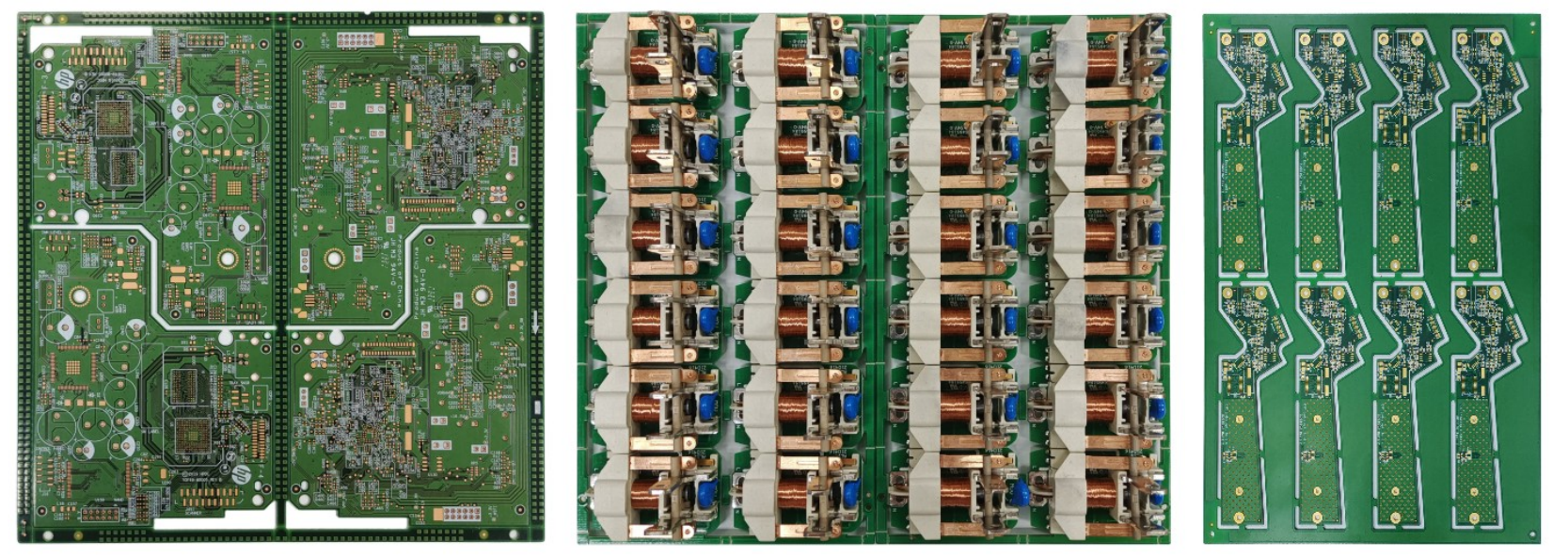

✧ Apply to

For cutting PCB circuit boards containing both V-grooves and point connections

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

✧ Company Information

Xiangjie Technology,founded in 2008, headquartered in Dongguan witch is the world's manufacturing capital. It is a supplier focusing on PCB circuit board cutting and soldering solutions, and is committed to providing standardized high-quality equipment and customized services to global users. After more than ten years of innovation and development, especially in the field of PCB cutting, Xiangjie Technology has become a leading manufacturer of SMT peripheral equipment in China and a world-renowned manufacturer. With a strong innovative R&D team and strong sales and after-sales service capabilities, it has served more than 30 countries and regions.

✧ Exhibition

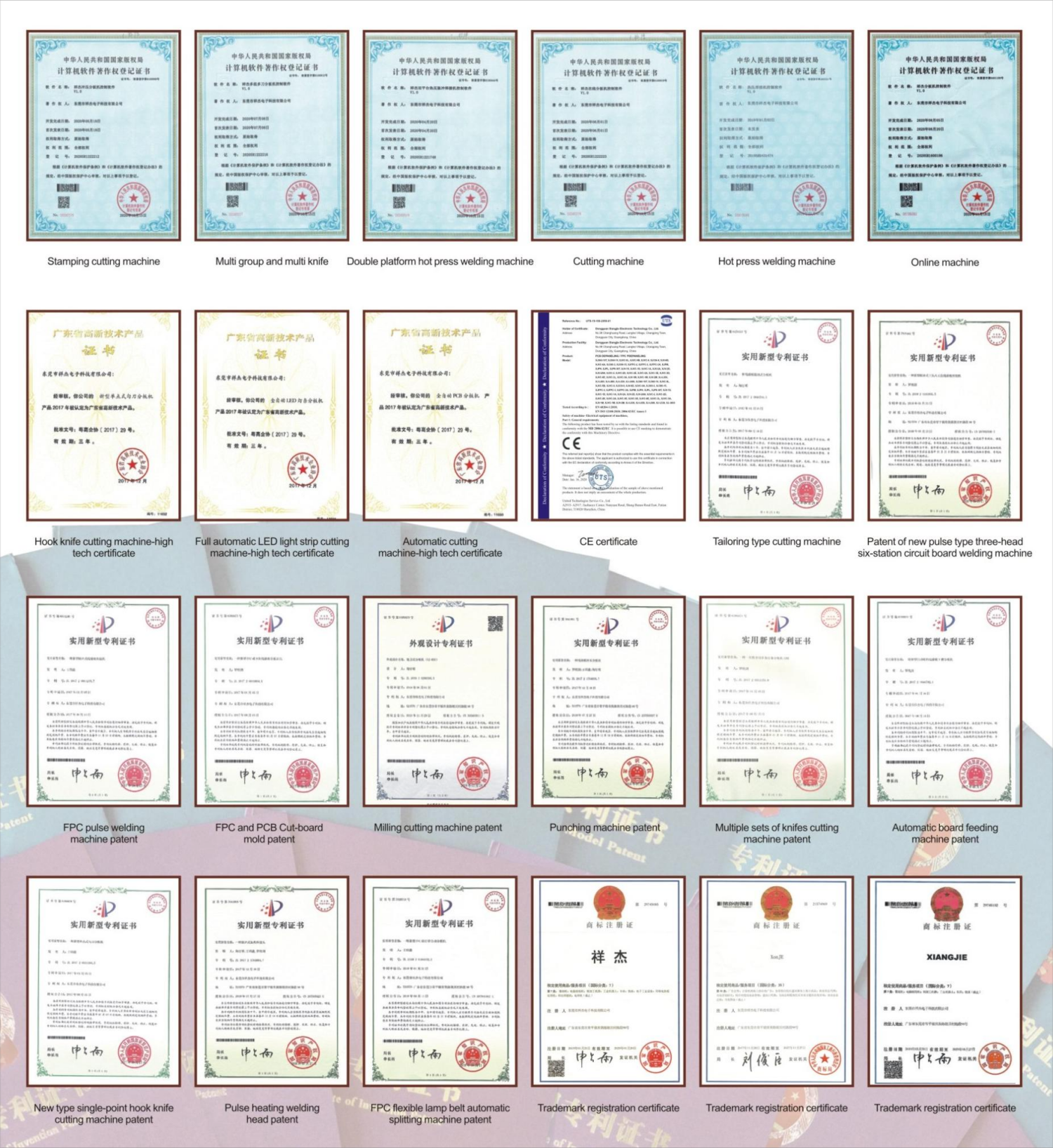

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

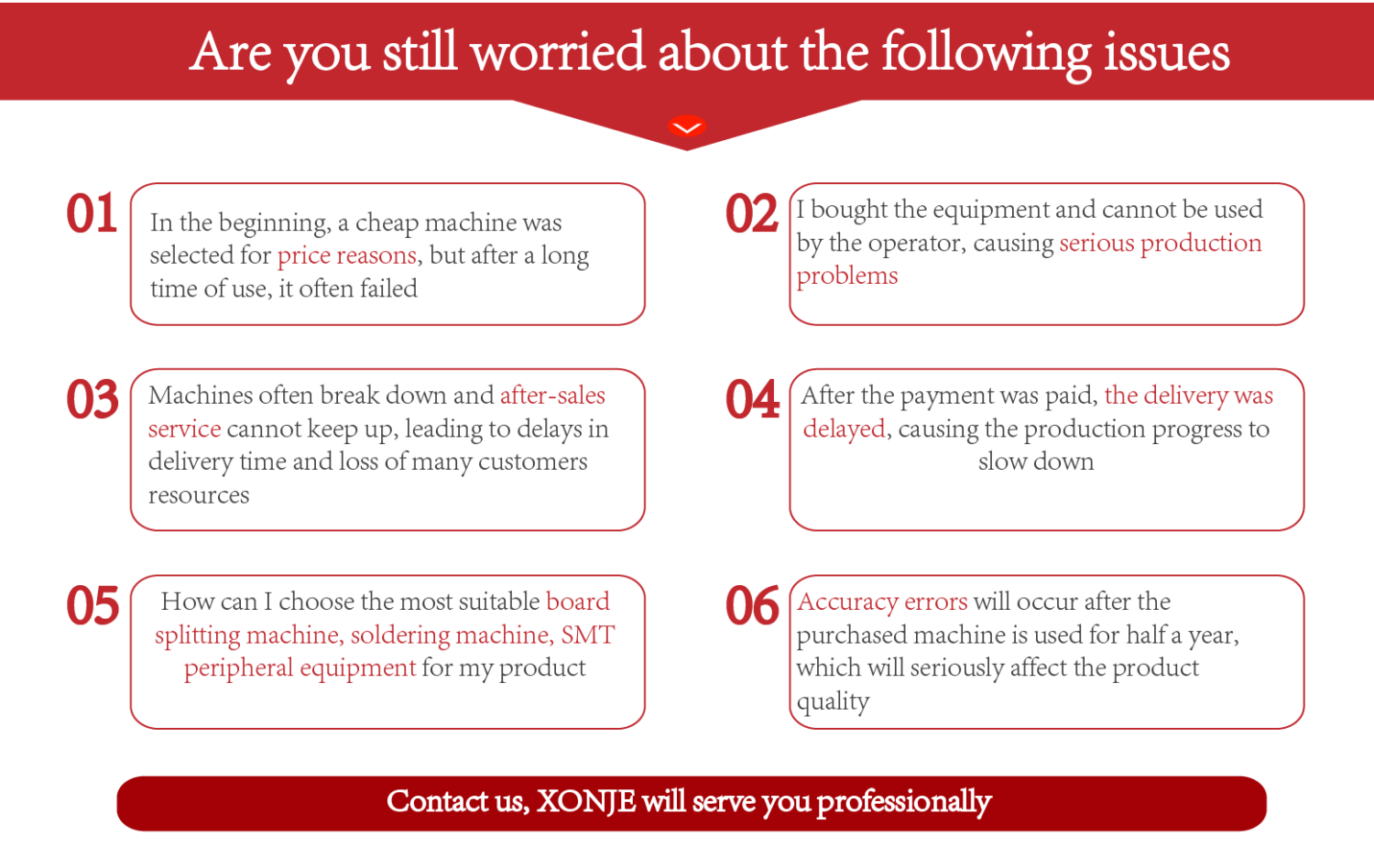

✧ FAQ

Q: What we can do for you?

A: Professional SMT peripheral equipment supplier; With more than ten years of mature industry experience

Q: Are you a trade company or manufacturer?

A: We are manufacturer with complete processing equipment

Q: What is your delivery date?

A: About 35 days after receipt of payment.

Q: What is your payment terms?

A: 100% balance before shipment.

Q: What your main customers?

A: PCB assembly manufacturer, SMT equipment manufacturer, light strip manufacturer, etc..

Q: Why choose you?

A: Leading SMT Supplier in China;

Trade assurance to USD 560,000+; Professional after-sales service team.