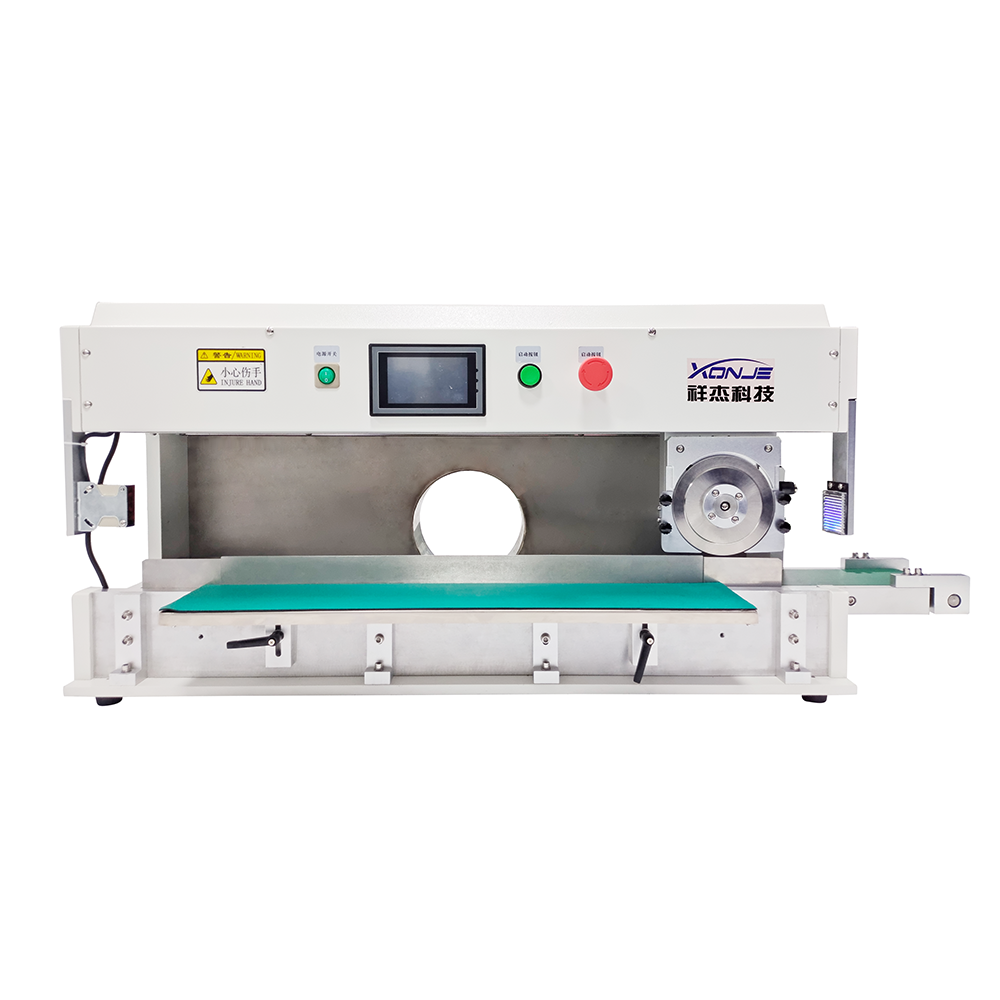

Electric PCB V-groove Cutting Machine

✧ Features

1 .The sliding speed of the round knife can be adjusted.

2. The PCB does not move during the cutting process, and the circular knife slips to ensure that the electronic components of the substrate are not damaged due to movement.

3.In response to the depth of the V groove and tool wear, the distance between the upper round knife and the lower straight knife can be adjusted accurately.

4. By customizing the blade, it is possible to realize the separation of components across the V-slot.

5. Minimize the internal stress generated when cutting the board to avoid tin cracking.

6. The slitting speed is controlled by the knob, and the slitting stroke can be set freely and has a touch screen display.

7. Conveyor belts can be installed as required to improve performance.

8. Equipped with photoelectric switch protection to ensure safe production.

✧ Technical Parameter

| Maximum cut-board length | 350mm, 600mm or customized |

| board splitting speed | 100/200/300/500mm/s Adjustable |

| board thickness | 0.3-3.5MM |

| working voltage | 220V AC 500W |

| Machine weight | 55KG |

| Dimensions(L*W*H) | 750*400*510MM |

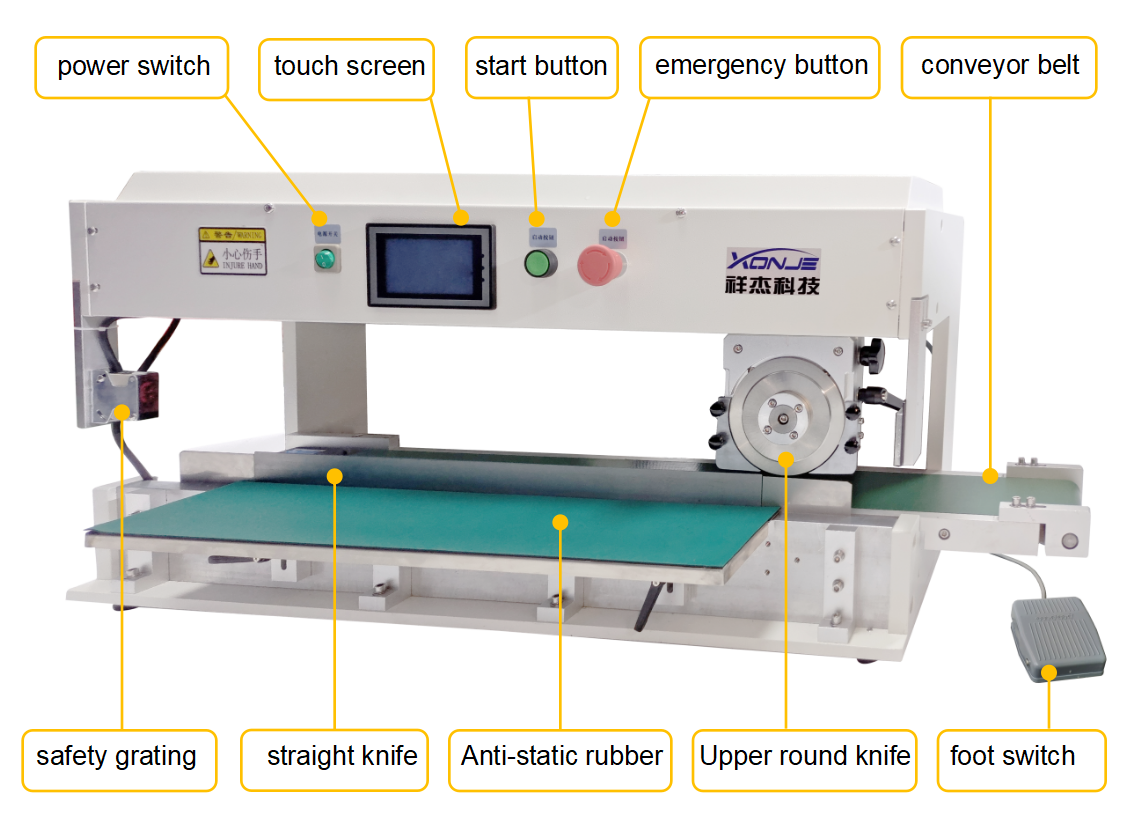

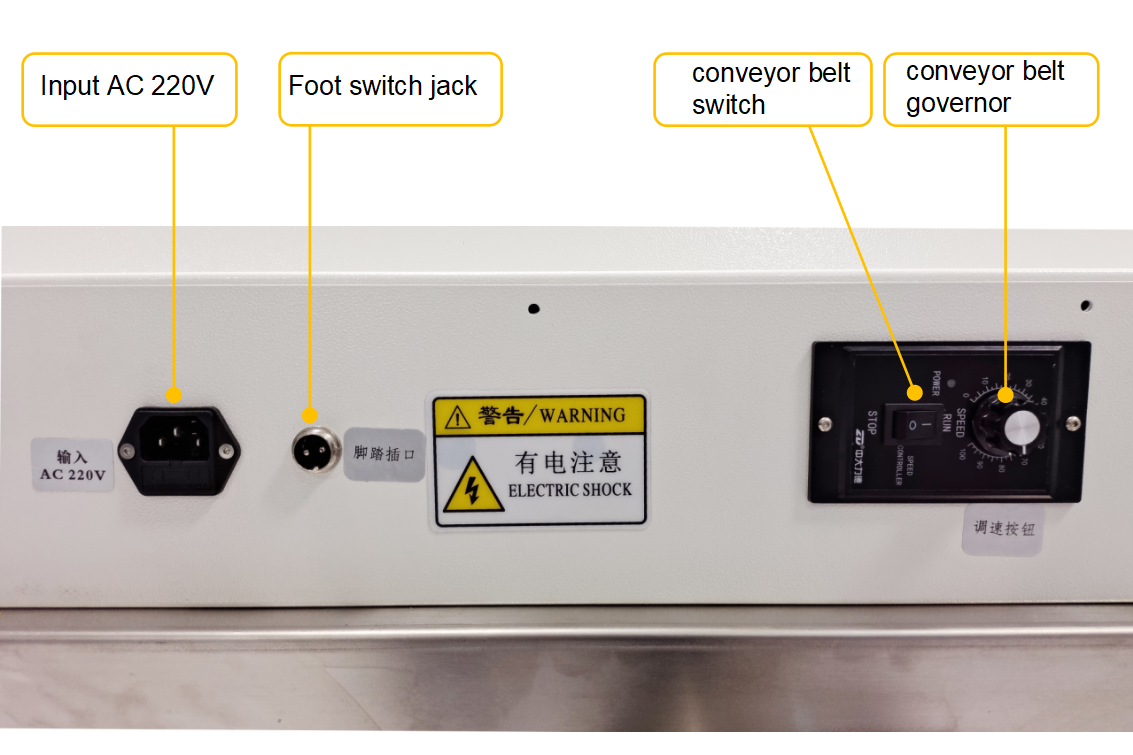

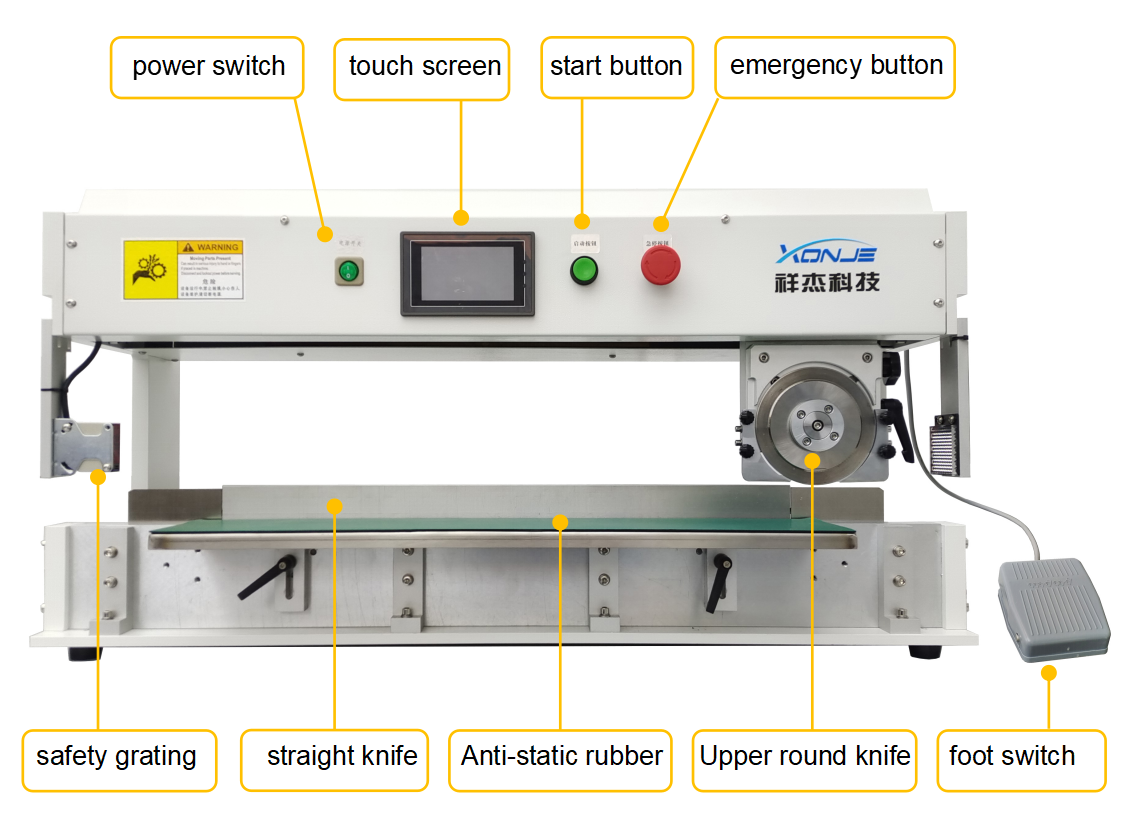

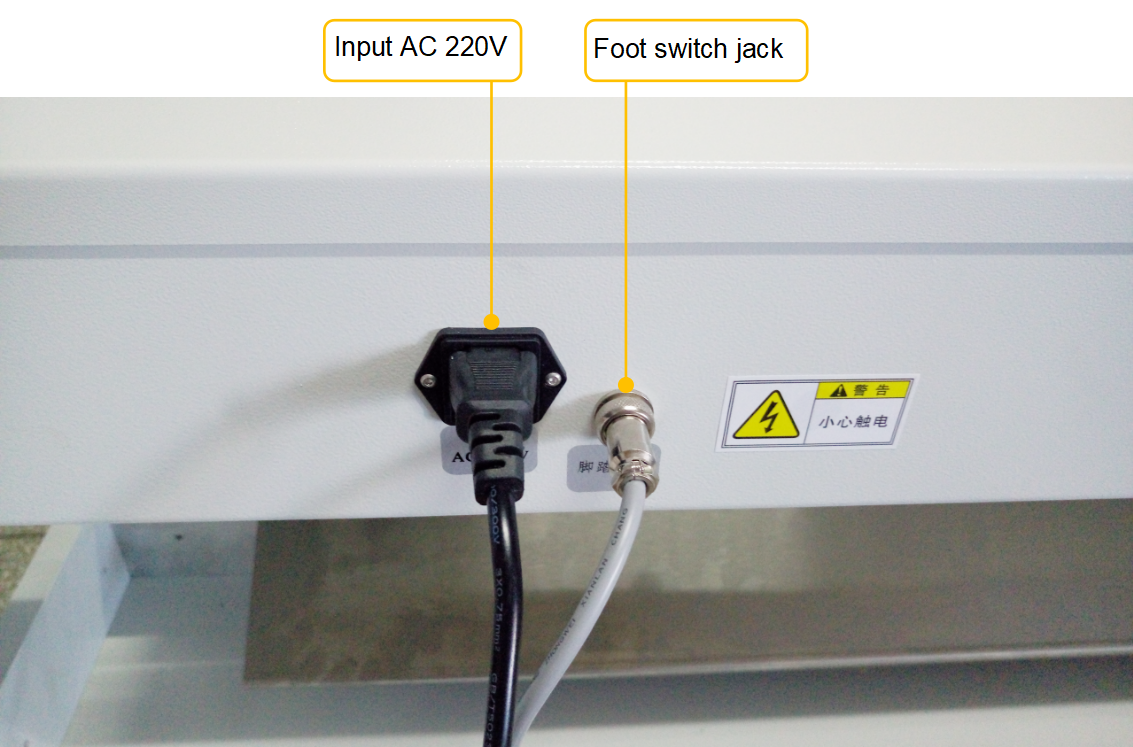

✧ Machine Structure

(1)Electric PCB V-groove Cutting Machine-without conveyor belt

(2)Electric PCB V-groove Cutting Machine-without conveyor belt

✧ Machine operation

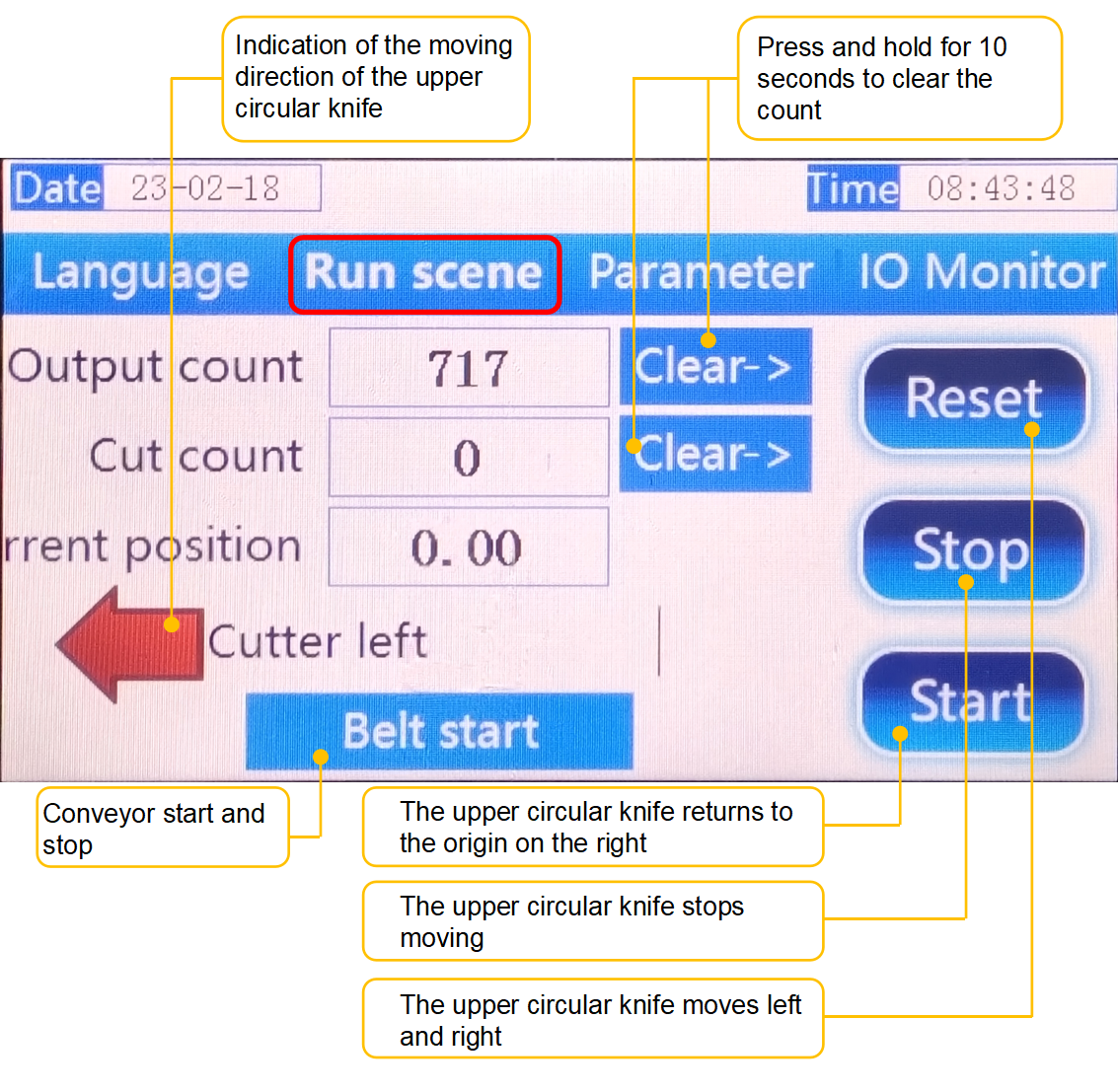

Interface description:

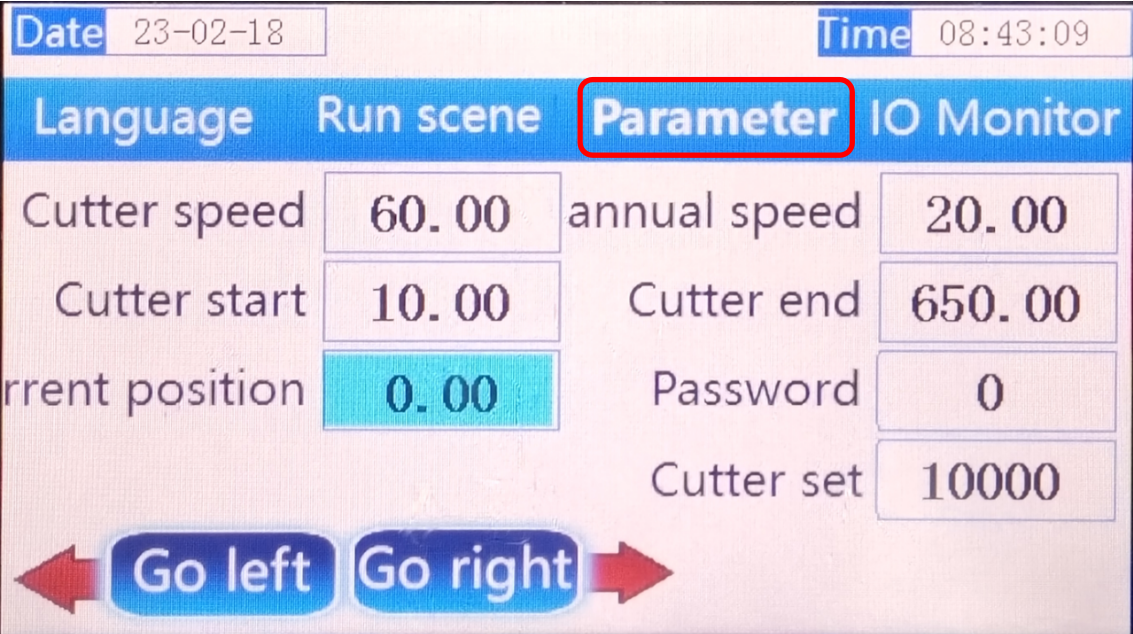

1. Parameter password: Enter the parameter setting interface and you can set a 1-8-digit digital password

2. Current coordinates: display the position realized by the upper circular knife

3. Cutting speed: 0-300 can be set arbitrarily, one move can be set according to the thickness and difficulty of the cutting board, the commonly used setting is 200

4. Manual speed: manual speed when the upper round knife moves left and right

5. The starting point of the cutting tool: the starting position of the upper circular knife can be set arbitrarily within the stroke range and it does not need to return to the original position every time.

6. The end point of the cutting tool: the upper circular knife can arbitrarily set the end position of the upper circular knife within the stroke range (it must be greater than the starting point of the cutting tool)

7. Round knife to the left: click on the upper circle knife to move to the left

8. Round knife to the right: click on the upper circle knife to move to the right

9. Return: Click Return to return to the running interface

screen (1)

screen (2)

screen (3)

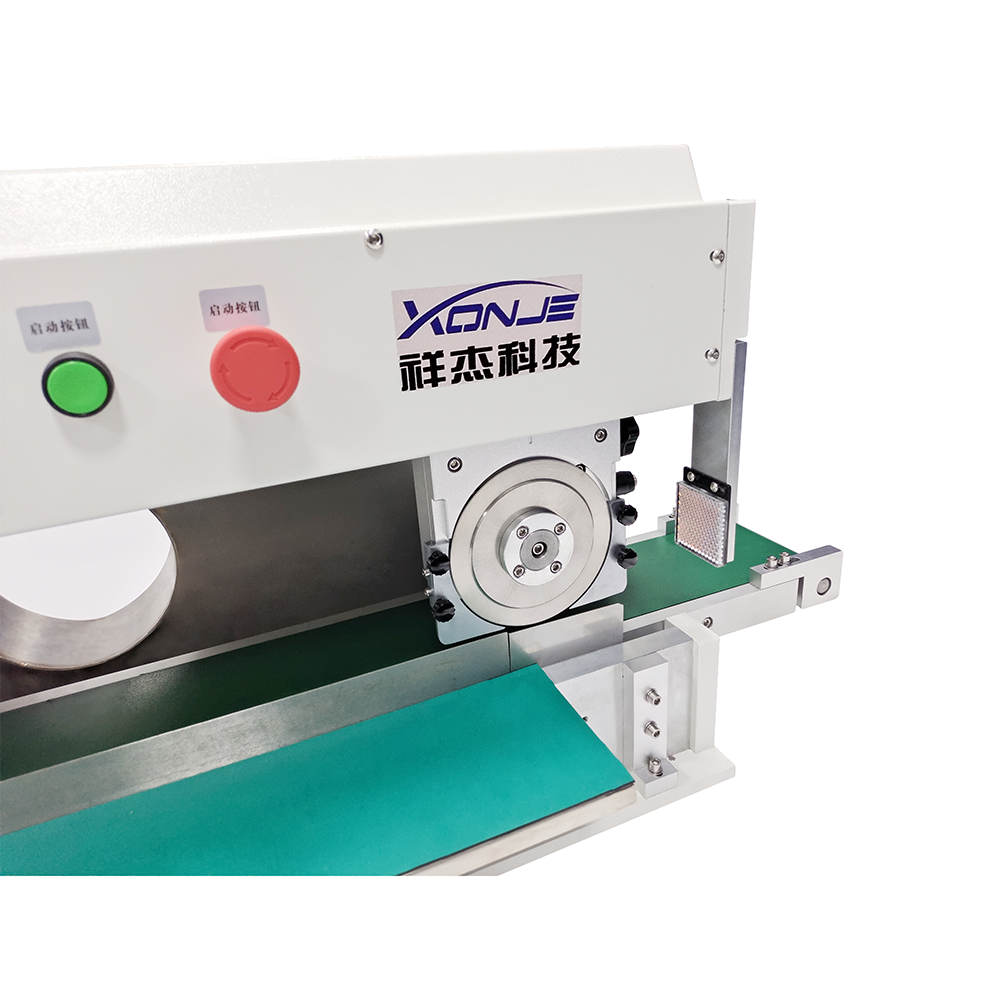

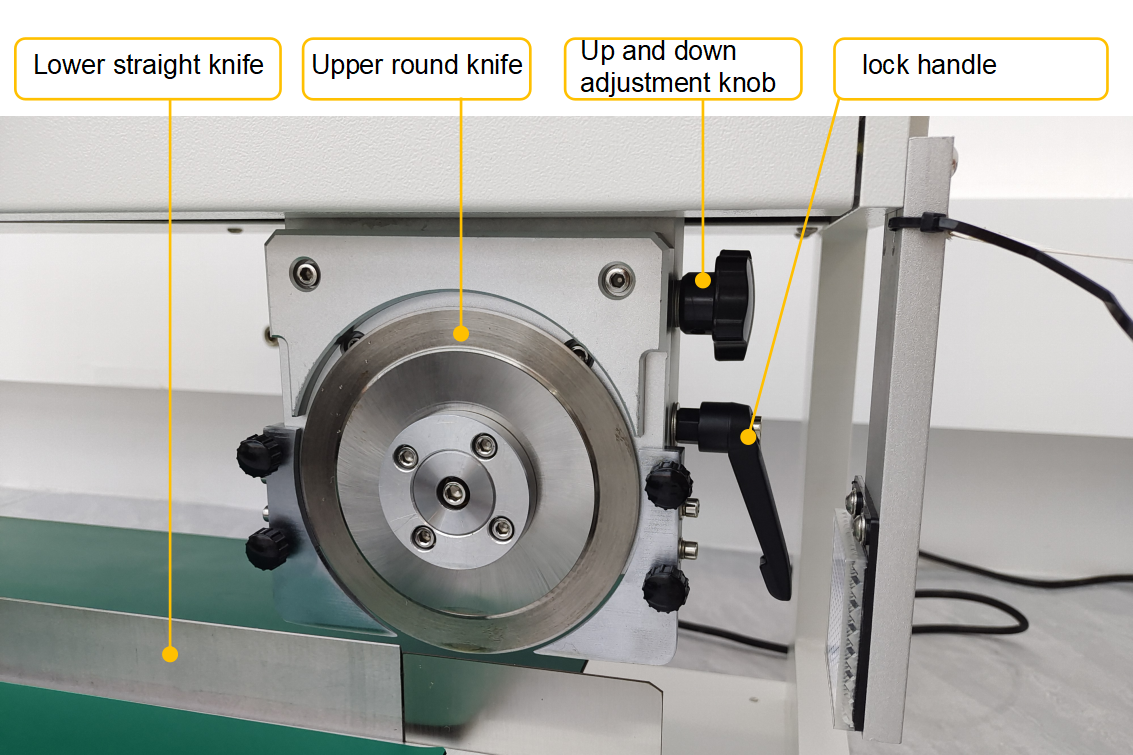

✧Round knife distance adjustment

Round knife distance adjustment

1. When the distance between the round knife and the knife is loosened, first loosen the locking handle and then rotate and adjust the knob to the desired distance.

2. When using a round knife, first use a 5MM hexagonal wrench to fix the middle screw, and then use a 4MM hexagonal wrench to loosen the four surrounding M5 screws.

✧matters needing attention

1. Do not extend your hands into the working area of the cutter to avoid accidents

2. It is not allowed to cut the substrate without V-groove

3. Do not take hard objects to the cutter for cutting

4. The parameters on the machine cannot be changed casually

5. Non-professional technicians are not allowed to open the control box

6. When replacing the blade, the power and gas should be cut off

✧Maintenance and maintenance

1. Clean up the dust and debris on the machine in time

2. Regularly (once a week) add grease to the moving parts

3. If any parts are damaged, they should be repaired immediately

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

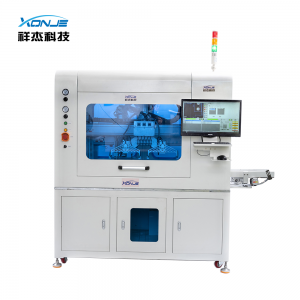

✧ Company Information

Xiangjie Technology,founded in 2008, headquartered in Dongguan witch is the world's manufacturing capital. It is a supplier focusing on PCB circuit board cutting and soldering solutions, and is committed to providing standardized high-quality equipment and customized services to global users. After more than ten years of innovation and development, especially in the field of PCB cutting, Xiangjie Technology has become a leading manufacturer of SMT peripheral equipment in China and a world-renowned manufacturer. With a strong innovative R&D team and strong sales and after-sales service capabilities, it has served more than 30 countries and regions.

✧ Exhibition

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

✧ FAQ

Q: What we can do for you?

A: Professional SMT peripheral equipment supplier; With more than ten years of mature industry experience

Q: Are you a trade company or manufacturer?

A: We are manufacturer with complete processing equipment

Q: What is your delivery date?

A: About 35 days after receipt of payment.

Q: What is your payment terms?

A: 100% balance before shipment.

Q: What your main customers?

A: PCB assembly manufacturer, SMT equipment manufacturer, light strip manufacturer, etc..

Q: Why choose you?

A: Leading SMT Supplier in China;

Trade assurance to USD 560,000+; Professional after-sales service team.