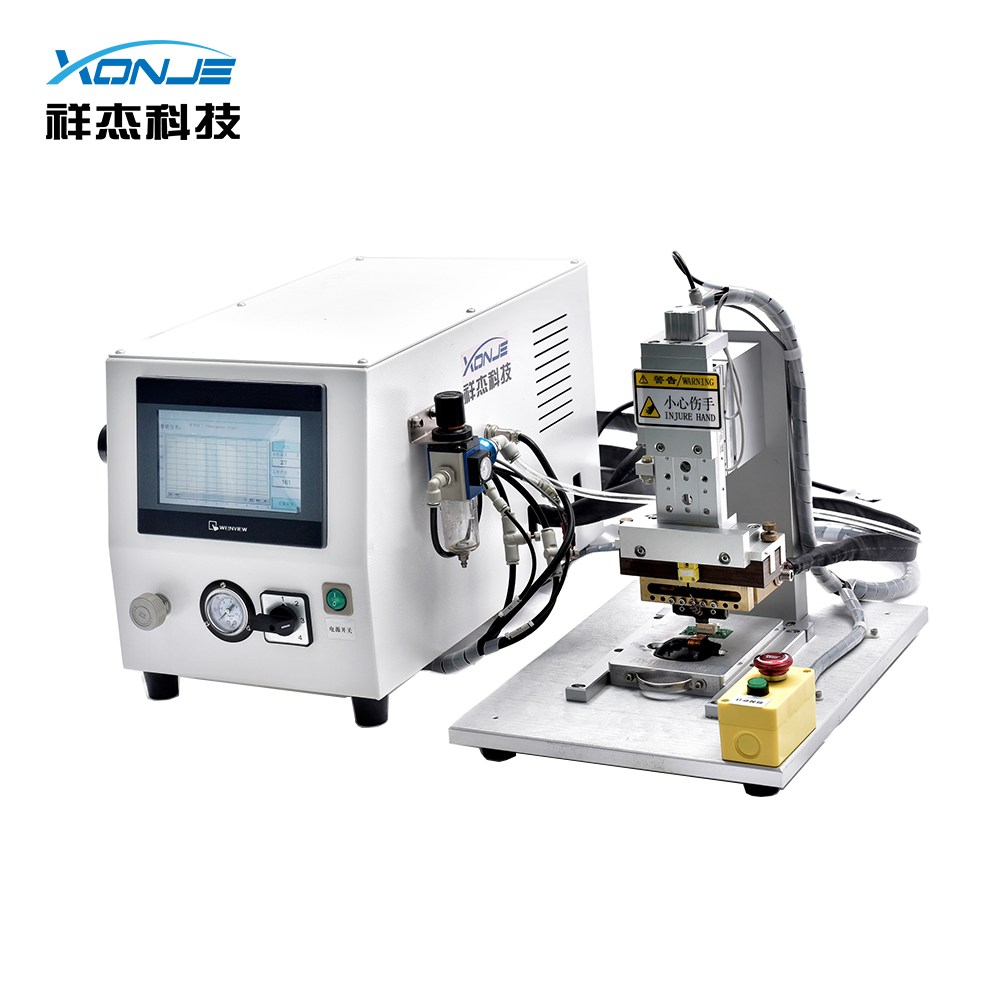

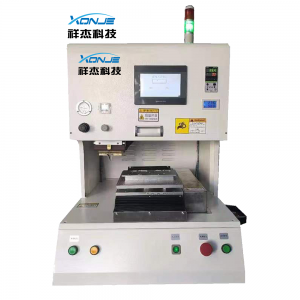

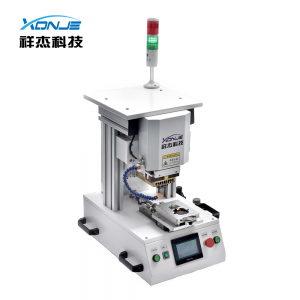

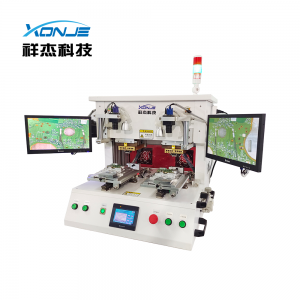

Split Pulse Soldering Machine

✧ Features

1 .According to different products, the heating speed can be adjusted.

2. Welding joints of special materials ensure that the product is balanced under pressure.

3. Equipped with vacuum function, it is easier to adjust the alignment.

4. The temperature is numerically controlled, clear and precise, touch screen operation, Chinese and English display interface, PLC control, simple operation.

5. Equipped with a digital pressure gauge, the pressure range can be preset, and the SMC precision guide rail cylinder is used, which has high pressure precision and can weld products with a solder joint spacing of 0.5MM.

6.Suitable for all kinds of high-density TAB, TCP crimping and FPC, FFC, TFT and PCB Solder crimping.

*Solder connection between FPC and PCB and connectors.

*Connection between ACF and PCB and connectors.

*Connection between TAB and PCB and connectors.

*Connection between TFT and PCB and connectors.

*Solder connection between FFC(flexible flat cable)and PCB and connectors.

*Solder connection between zebra paper and PCB and connector.

*Solder connection between ultra-fine coaxial cable and PCB and connector.

*Solder connection of enameled wires such as hard disks.resistors,capacitors,coils,transformers,IC cards,etc.

*Solder connection between battery pole piece and PCB and connector.

*Soldering connection of winding terminals of small motors. Resin thermocompression bonding for relays, printers,glasses, etc.

✧ Technical Parameter

| Workbench area | 400*400mm | X.Y.Z stroke | 350*380*50mm |

| Display screen | 17 inch computer display | Dust collection method | Optional upper dust collection or lower dust collection |

| Screw/rail | HIWIN | Spindle speed | 2000-60000rpm/min |

| Drive System | Three-axis servo motor | Spindle tool | φ0.8-3mm |

| Positioning accuracy | ±0.01mm | Cutting speed | 0-100mm/sec |

| Cutting function | Executable straight line, L type,U type, arc,Full circle cut | Control host | Industrial Computer |

| Machine size | L830*W1020*H1400mm | Dust box size | L700*W400*H720mm |

| Power | Three-phase 380V/3KW with vacuum cleaner | Machine weight | 240KG |

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

✧ Company Information

Xiangjie Technology,founded in 2008, headquartered in Dongguan witch is the world's manufacturing capital. It is a supplier focusing on PCB circuit board cutting and soldering solutions, and is committed to providing standardized high-quality equipment and customized services to global users. After more than ten years of innovation and development, especially in the field of PCB cutting, Xiangjie Technology has become a leading manufacturer of SMT peripheral equipment in China and a world-renowned manufacturer. With a strong innovative R&D team and strong sales and after-sales service capabilities, it has served more than 30 countries and regions.

✧ Exhibition

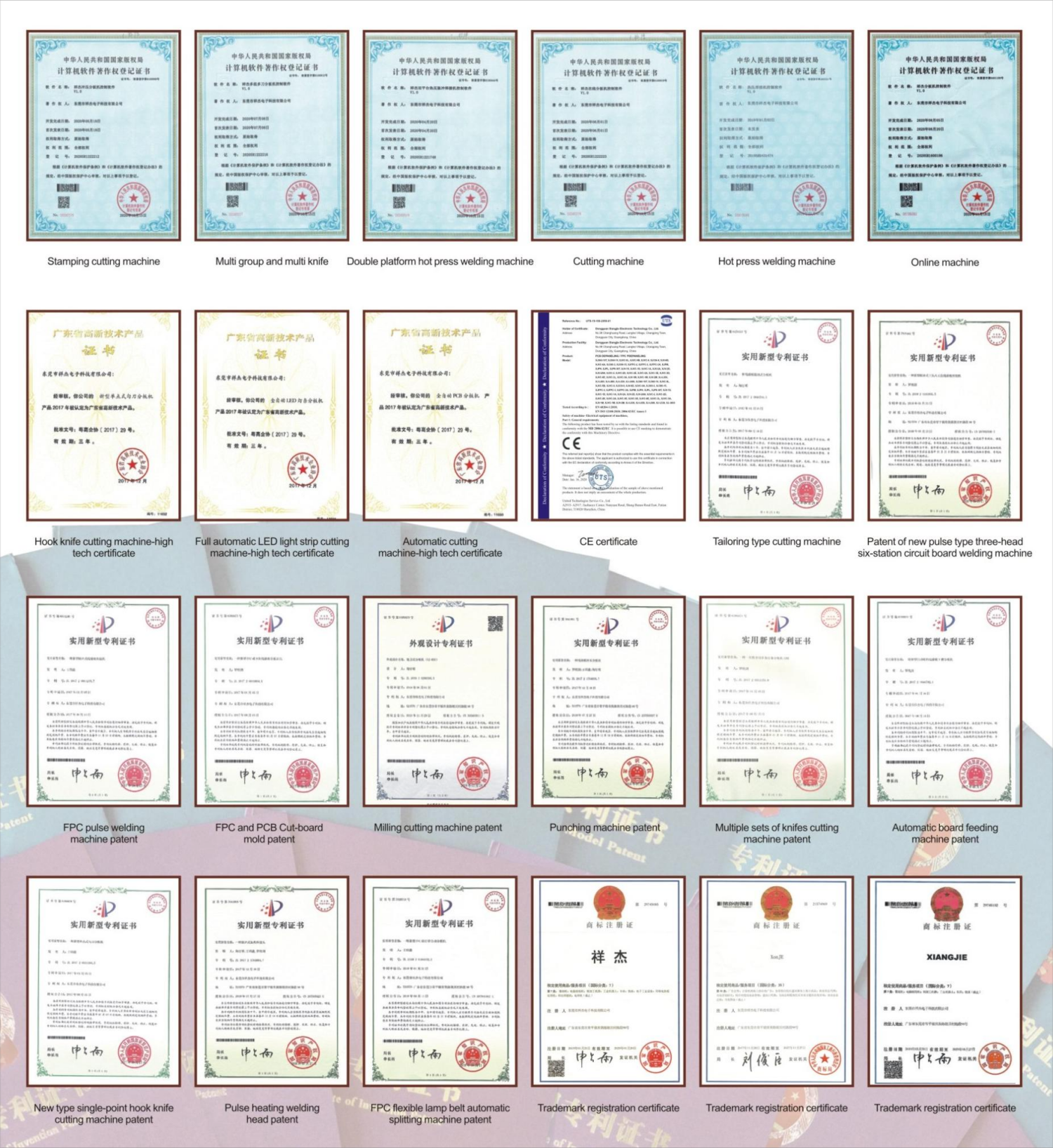

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

✧ FAQ

Q: What we can do for you?

A: Professional SMT peripheral equipment supplier; With more than ten years of mature industry experience

Q: Are you a trade company or manufacturer?

A: We are manufacturer with complete processing equipment

Q: What is your delivery date?

A: About 35 days after receipt of payment.

Q: What is your payment terms?

A: 100% balance before shipment.

Q: What your main customers?

A: PCB assembly manufacturer, SMT equipment manufacturer, light strip manufacturer, etc..

Q: Why choose you?

A: Leading SMT Supplier in China;

Trade assurance to USD 560,000+; Professional after-sales service team.