Online Turntable V-slot Cutting Machine

✧ Features

This device is suitable for cutting the PCB board after plug-in work. It has functions of automatic loading, cutting and unloading board, etc., and is easy and quick to operate. The setting of various parameters ensures the continuity of board loading and cutting. The main transmission components adopt precision stepping motors and servo motors, and the pneumatic components adopt international brands, which makes the repeat positioning accuracy high. The whole machine adopts Mitsubishi PLC + WEINVIEW touch screen control, with a simple and convenient operation interface. The working voltage is 220V 50Hz, and the efficiency is 25s/pcs (150*150mm, 4 cuts for reference). The working area is protected by a safety photoelectric switch.

✧ Technical Parameter

| 1.Equipment appearance specifications | Machine name | On-line automatic two-way Cutting Machine |

| Machine model | XJVC-10A | |

| Overall dimension | L*W*H=1600*1100*1800mm | |

| appearance | vertical | |

| weight | 600KG | |

| colour | Computer white | |

| 2.equipment supply requirements | Power supply | AC220V 3000W |

| Environmental requirements | Clean and dry environment and avoid humidity or high temperature | |

| Working pressure / pipe diameter | ≥0.6MP/8MM | |

| Minimum distance from part to the cutting line | ≥1.5MM | |

| Maximum and minimum partition | 300*300MM & 12*12MM | |

| Suction cup requirements | At least one side of a single small board shall have a space greater than 10mm * 10mm | |

| board inlet adjustment | Direct input of parameters, automatic adjustment) | |

| Maximum height of PCB | The height limit of PCB reverse side parts is 20mm and the height limit of front side is 35mm | |

| 3. equipment software | Controller | PLC |

| Parameter setting | According to the size of the V-slot, it is input directly from the touch screen | |

| Storage module | It can store 50 groups of programs | |

| touch screen | WEINVIEW touch screen | |

| Optical fiber sensor | OMRON | |

| 4.blade | Metal properties | High speed steel imported from Japan |

| Blade angle | 10-30Degree (optional) | |

| service life | 5KM | |

| Knife mold accuracy | 0.1MM | |

| 5.Main control cut-board system | Replacement time of cutter set and suction cup | 60minute |

| Board splitting efficiency | standard speed cut 4 knives,25s/pcs(200*150mm) | |

| Step Servo | Precision stepper motors and servo motors | |

| Guide screw | HIWIN Guide rail screw | |

| Pneumatic accessories | AIRTAC/SMC | |

| Maximum length and width of pipeline | 650mm*250mm( customizable) | |

| Board splitting speed | 0-800mm/s | |

| Knife mold base movement mode | Servo system + screw guide rail | |

| Suction cup manipulator motion control mode | Stepper motor + guide rail + belt drive | |

| Dust collection mode and efficiency | Dust suction under knife set 1500W | |

| Thickness of slitting board | 0.4-3.5mm | |

| 6.other functions | Misoperation protection | Triple protection of grating sensor and software |

| Part surface treatment | Anodic plating | |

| safety protection | Emergency stop | |

| Power off and gas cut-off function | yes | |

| Self checking function | Startup time monitoring, capacity monitoring, equipment fault information and automatic rejection system | |

| main part of the equipment | board loading machine (assembly line), suction cup, three-axis moving board splitting platform, vacuum cleaner | |

| operation mode | Automatic manipulator on-line cutting and feeding board | |

| Scope of application | Two-way V-slot of PCB after plug-in / SMD |

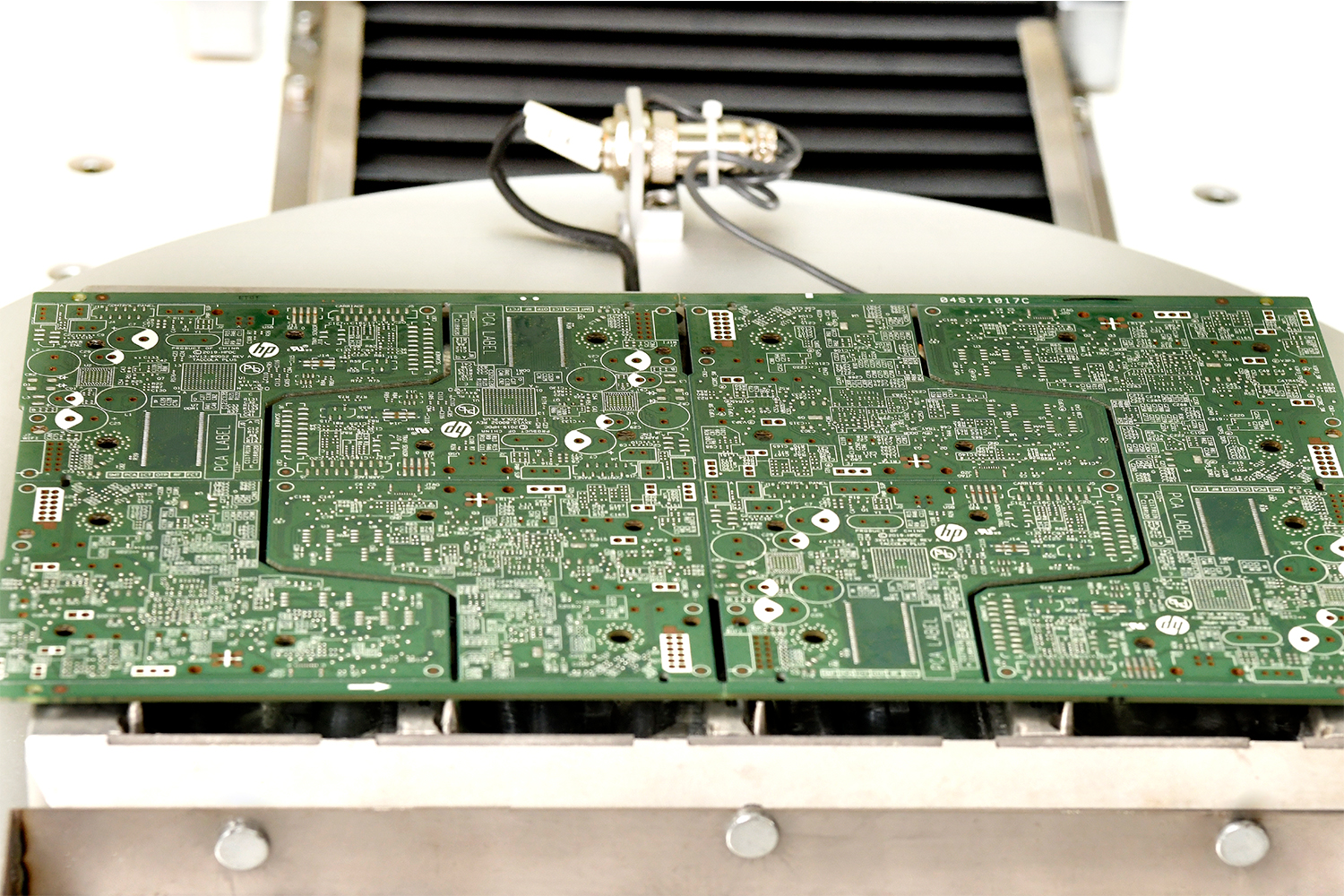

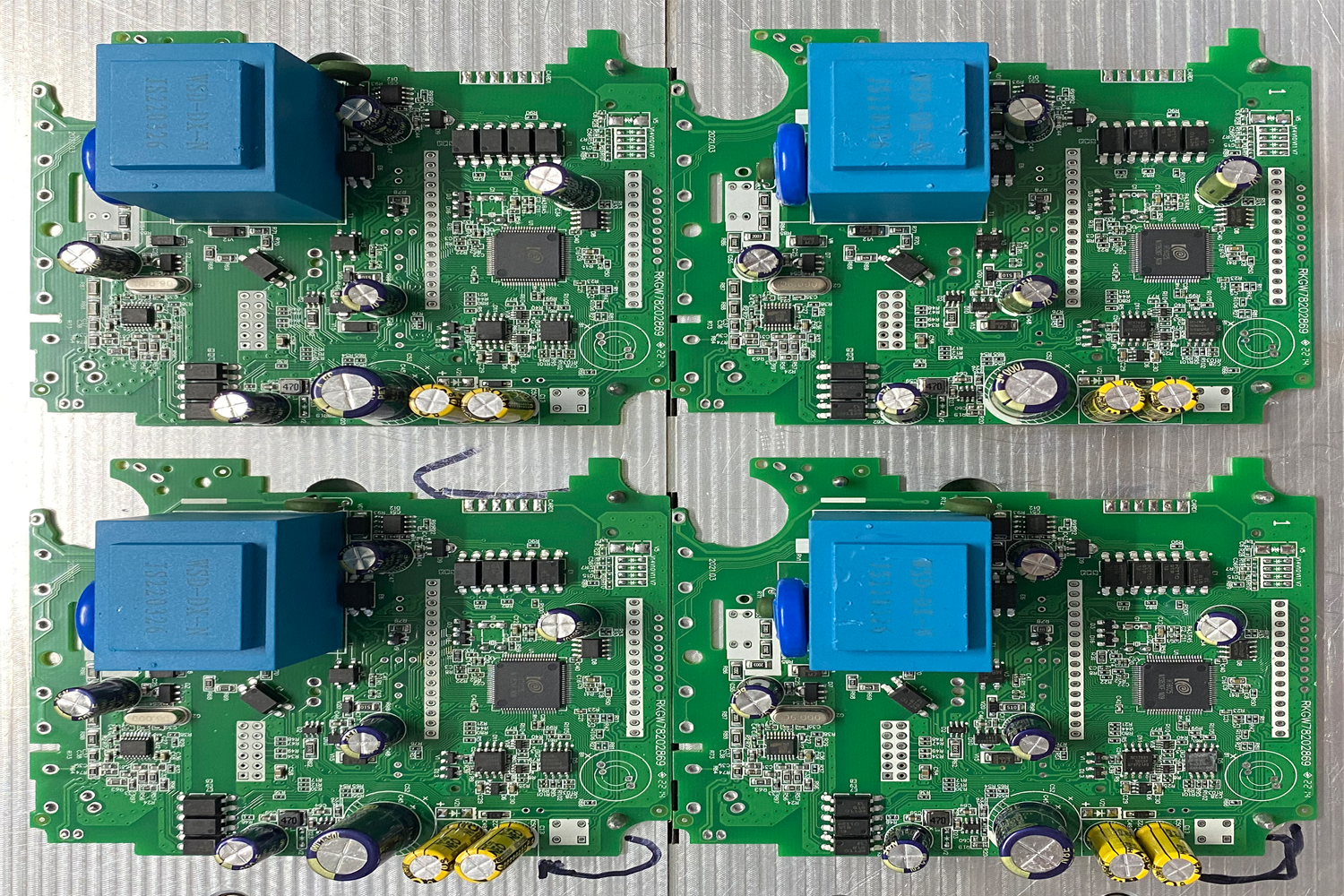

✧ Apply To

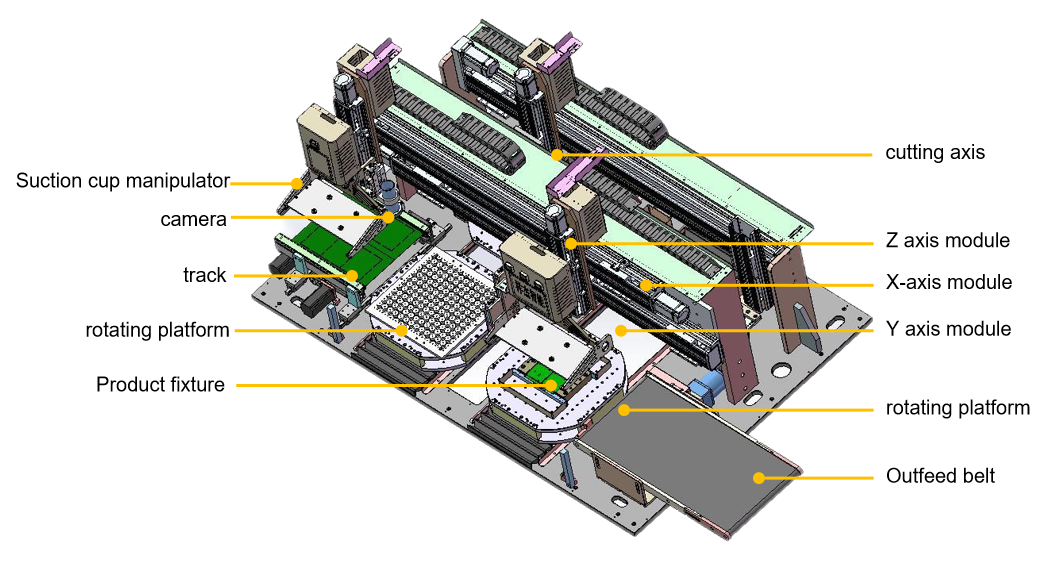

✧ Machine Structure

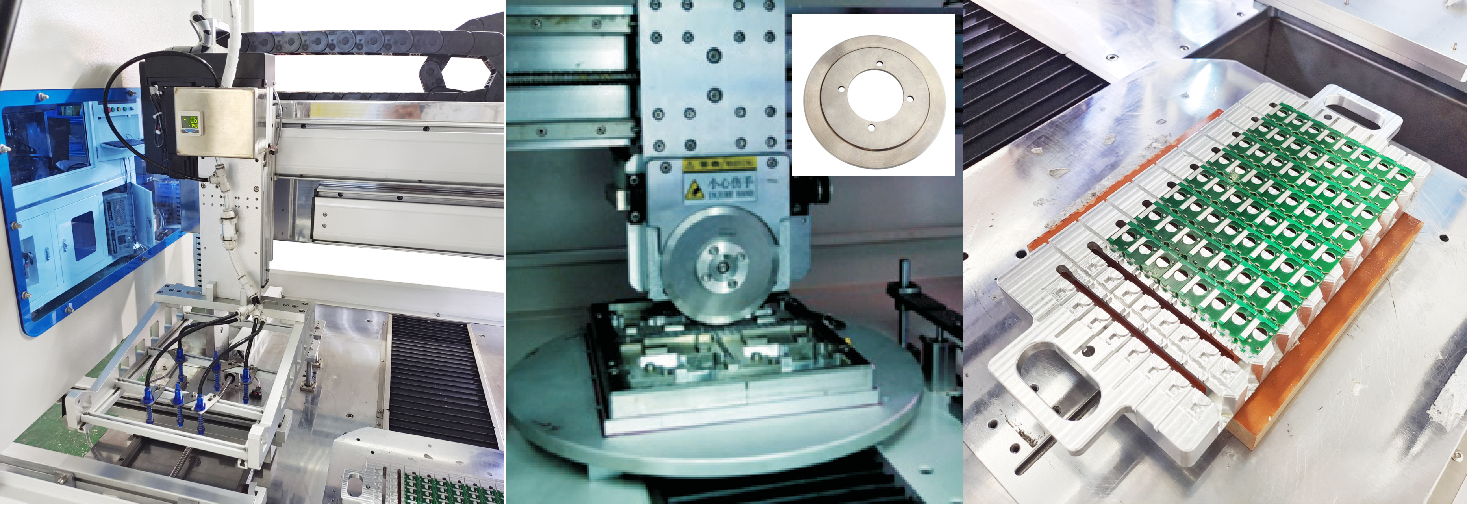

✧ Accessories

Product Suction Cup

Cutting round blade

Product fixture

✧ Packaging & Shipping

Wooden packing

Wooden packing

✧ Transport Way

→ By air:for sample and small package, international express like DHL, UPS, EMS...

→ By sea: for large package and quantity;

→ Other ways as customer requested.

Delivery Time:

→ Within 35 Days.

✧ Company Information

Xiangjie Technology,founded in 2008, headquartered in Dongguan witch is the world's manufacturing capital. It is a supplier focusing on PCB circuit board cutting and soldering solutions, and is committed to providing standardized high-quality equipment and customized services to global users. After more than ten years of innovation and development, especially in the field of PCB cutting, Xiangjie Technology has become a leading manufacturer of SMT peripheral equipment in China and a world-renowned manufacturer. With a strong innovative R&D team and strong sales and after-sales service capabilities, it has served more than 30 countries and regions.

✧ Exhibition

✧ Trademark & Patent

Xiangjie Technology has obtained a number of invention patents, more than 30 practical patents and a variety of high-tech products.

✧ FAQ

Q: What we can do for you?

A: Professional SMT peripheral equipment supplier; With more than ten years of mature industry experience

Q: Are you a trade company or manufacturer?

A: We are manufacturer with complete processing equipment

Q: What is your delivery date?

A: About 35 days after receipt of payment.

Q: What is your payment terms?

A: 100% balance before shipment.

Q: What your main customers?

A: PCB assembly manufacturer, SMT equipment manufacturer, light strip manufacturer, etc..

Q: Why choose you?

A: Leading SMT Supplier in China;

Trade assurance to USD 560,000+; Professional after-sales service team.